Let me be honest with you right from the start:

Most workers—heck, even some supervisors—think inspecting fall protection equipment is as simple as giving it a quick look, tugging on a strap, spinning a buckle, and calling it good.

I’ve lost count of how many times someone handed me a harness still wet from last week’s rain and said, “Boss, check mo kung okay pa.”

And I’m standing there thinking,

My guy… this thing smells like a wet dog and looks like it wrestled with a grinder… why are we even debating this?

But that’s the problem.

A lot of people don’t understand who is actually allowed to inspect and certify fall protection gear—and more importantly, why the rules are so specific.

Fall protection inspections aren’t just a “safety thing.”

They’re a liability thing, a manufacturer requirement, a recordkeeping thing, a compliance thing, and a “let’s not fall 20 feet to the ground today” thing.

So let’s break it down.

Not the polished corporate way—let’s talk like real people who actually deal with this stuff.

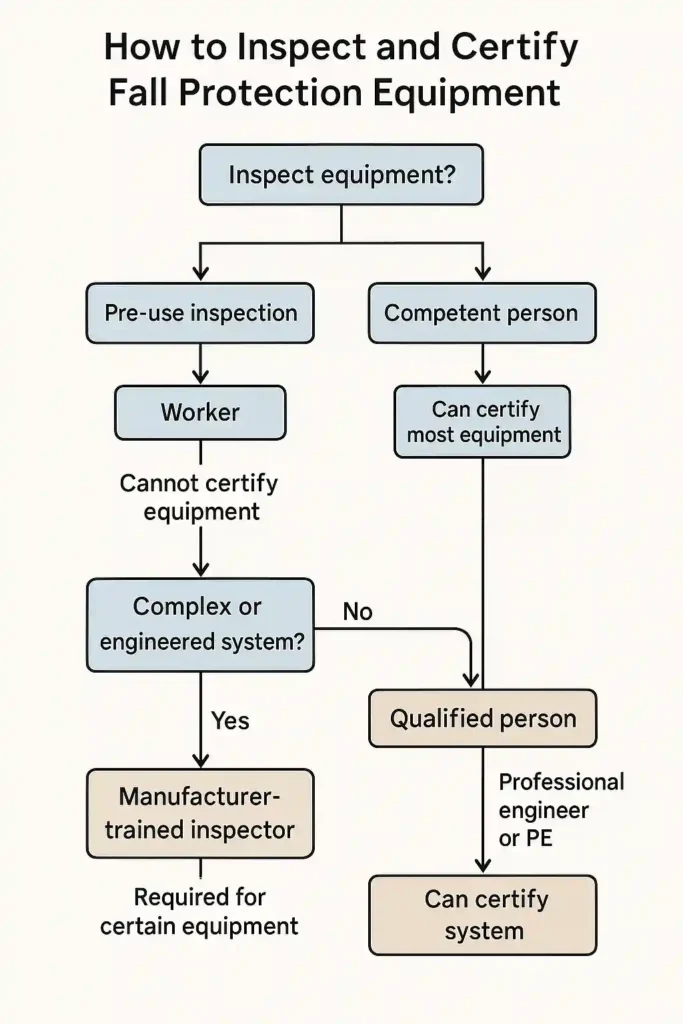

Who Can Inspect and Certify the Equipment

| Role | Can Inspect Daily? | Can Perform Formal Inspection? | Can Certify/Approve Equipment? | Can Remove Gear From Service? | Notes |

|---|---|---|---|---|---|

| Authorized Person (Worker) | ✔ Yes | ❌ No | ❌ No | ✔ Yes (tag out) | Daily pre-use checks only |

| Competent Person | ✔ Yes | ✔ Yes | ✔ Yes (for most equipment) | ✔ Yes | Jobsite inspection authority |

| Qualified Person | ✔ If needed | ✔ For engineered systems | ✔ Yes | ✔ Yes | Engineer-level expertise |

| Manufacturer / Certified Technician | ✔ Yes | ✔ Yes | ✔ Yes (full certification) | ✔ Yes | Required for SRLs, repairs, recertification |

| Foreman / Supervisor (not designated CP) | ✔ Possibly | ❌ No | ❌ No | ❌ Limited | Depends on designation |

When Each Person Is Needed

| Inspection Type | Who Performs It | Frequency | Equipment Covered | Notes |

|---|---|---|---|---|

| Daily Pre-Use Check | Authorized Person | Every shift | Harness, lanyards, D-rings, stitching | Not a certification |

| Formal Jobsite Inspection | Competent Person | Monthly or quarterly | All fall protection gear | Employer-designated authority |

| Annual Manufacturer Inspection | Manufacturer / Certified Tech | Yearly | SRLs, retractables, advanced gear | Required by many brands |

| Engineering Review | Qualified Person | As needed | Anchor systems, lifelines, custom systems | Needed for complex setups |

| Post-Fall Event Inspection | Manufacturer / Competent Person | Immediately after fall | Any gear involved in a fall | Most gear gets removed permanently |

What Workers Check vs. What Competent Persons Check

| Component | Worker (Daily Check) | Competent Person (Formal Check) |

|---|---|---|

| Webbing | ✔ | ✔ (detailed, with criteria) |

| Stitching | ✔ | ✔ (close inspection, magnification if needed) |

| D-Rings/Hardware | ✔ | ✔ (load deformity checks) |

| Labels | ✔ | ✔ (must be legible) |

| Shock Pack | ✔ | ✔ (full inspection, deployment check) |

| SRL Internal Mechanism | ❌ | ✔ Only manufacturer-trained |

| Recordkeeping | ❌ | ✔ Must document results |

| Removal from Service | ✔ Tag out | ✔ Officially remove |

Not All Gear Needs the Same Kind of Inspector

Here’s something most workers don’t realize:

Different fall protection equipment has different inspection rules.

A simple full-body harness?

Your competent person can inspect that.

A twin-leg self-retracting lifeline (SRL)?

That’s a whole different animal.

Some gear has springs, internal brakes, tension systems, speed-sensing pawls—stuff you can’t see without opening it. And guess what? You’re not allowed to open it unless you’re manufacturer-trained.

Even different brands of harnesses have different retirement criteria. One brand might allow a minor fray; another considers it out of service immediately.

So right off the bat, we have inspection tiers, not “one-size-fits-all.”

Here’s How The Inspection and Certification is Done

Equipment Types & Who Can Certify Them

| Equipment Type | Can Worker Inspect? | Can Competent Person Certify? | Must Manufacturer Certify? |

|---|---|---|---|

| Full Body Harness | ✔ | ✔ | ❌ |

| Shock-Absorbing Lanyard | ✔ | ✔ | ❌ |

| Positioning Lanyard | ✔ | ✔ | ❌ |

| Self-Retracting Lifeline (SRL) | ✔ (external only) | ❌ | ✔ Required |

| Horizontal Lifeline | ❌ | ❌ | ✔ Qualified + Manufacturer |

| Anchor Point (engineered) | ❌ | ❌ | ✔ Qualified Person |

| Rope Grabs | ✔ | ✔ | Optional (depends on brand) |

Defects and Who Is Allowed to Make the Call

| Defect Type | Worker Can Tag Out? | Competent Person Can Decide? | Manufacturer Required? |

|---|---|---|---|

| Frayed Webbing | ✔ | ✔ | Optional |

| Burn Marks | ✔ | ✔ | Optional |

| Missing Stitch Lines | ✔ | ✔ | Optional |

| Bent D-ring | ✔ | ✔ | ❌ Usually manufacturer |

| Shock Pack Deployment | ✔ | ✔ | Optional |

| Cracked SRL Housing | ✔ | ❌ | ✔ Required |

| Internal SRL Mechanism Issue | ❌ | ❌ | ✔ Always |

The “Nope List”: People Who Should NOT Inspect or Certify Gear

Let’s have a little fun here—because it’s true and because I’ve seen it.

❌ The new guy who still wears his harness backwards

❌ The foreman who says “It’s fine, I used gear like that in 1998”

❌ Anyone who has never actually read a fall protection manual

❌ The person who says “If it hasn’t broken yet, it won’t break today”

❌ The one who signs inspection logs without actually doing the inspection

❌ Anyone who thinks duct tape is an acceptable repair method

❌ The person who is terrified to tell management “no”

If you recognize any of those people on your jobsite…

just take the gear, put it in the “Do Not Use” bin, and walk away.

Recordkeeping: The Side of Certification Everyone Forgets

Inspection isn’t just looking at gear—it’s also documenting what you saw.

Real certification includes:

- Serial numbers

- Batch numbers

- Date of inspection

- Name of inspector

- Condition notes

- What was replaced

- Photographs of defects

- Sticker or tag updates

Some companies even require:

- Digital logs only

- Timestamped entries

- QR code tracking on harnesses

All this matters because if something ever goes wrong, investigators will examine inspection logs line by line.

Final Thoughts: When in Doubt, Throw It Out

Here’s my personal rule—and I encourage every competent person to use it:

If I’m even 10% unsure about a piece of gear, it’s out. No discussion.

Why?

Because the consequences of gambling with fall protection equipment are too big.

There’s no pride in using old gear.

There’s no heroism in ignoring damage.

There’s no medal for “being tough” with a frayed lanyard.

So the next time someone hands you questionable equipment and asks, “Boss, pwede pa ba ‘to?”, you can smile and say:

“Let’s check it properly… and if I don’t like what I see, we’re getting you a new one.”

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

View All Articles