If you’ve ever picked up your safety harness, looked at the frayed webbing or faded label, and asked yourself, “Is this thing still safe to use?” — you’re not alone.

I’ve worked around fall protection long enough to know that almost everyone has the same question, but nobody gets a straight answer.

Some guys say harnesses only last 3 years.

Others swear theirs is still good after a decade.

Then you’ve got the supervisors who shrug and say, “As long as it looks fine.”

And if you check OSHA?

Well… OSHA doesn’t even give a specific expiration date for harnesses.

So what’s the real answer?

Let me give it to you straight — not from a rulebook, but from real jobsite experience and what I’ve learned from actually using, inspecting, and retiring harnesses over the years.

The Real Answer: It Depends (And I Know You Hate That)

I know “it depends” sounds like a lazy answer, but stick with me because it’s the truth.

Fall protection harnesses don’t have a universal shelf life.

OSHA doesn’t say, “Replace your harness every 5 years” or anything like that.

But manufacturers do give guidance, and your work environment also plays a huge role.

Here’s the honest, real-world expectation:

- If you take good care of your harness: it can last 5–10 years.

- If you use it daily in a harsh environment: expect 3–5 years.

- If you abuse it or store it terribly: I’ve seen harnesses fail in less than a year.

So the lifespan isn’t a fixed number.

It comes down to one thing:

The condition of the harness — not its birthday.

And that’s exactly how OSHA looks at it.

Why Harness Lifespan Isn’t Just About Age

Let me explain this in a simple way.

Imagine two harnesses:

Harness A:

- Used once a week

- Stored in a clean locker

- Kept out of the sun

- Cleaned occasionally

- Inspected regularly

This one might last 7, 8, maybe even 10 years.

Harness B:

- Used daily on a construction site

- Tossed in a dusty truck bed

- Baked in the sun

- Soaked during rain

- Covered in grime

This one might be lucky to last 2 years.

Same product.

Different lifespan.

Because condition is everything.

Harness Lifespan Based on Usage & Conditions

Not all harnesses age the same. A harness that lives in a clean warehouse can last nearly a decade, while one used on a sunny rooftop might barely survive a couple of years.

How long yours actually lasts comes down to how often you use it, where you use it, and how well you treat it. Here’s a quick breakdown of what you can realistically expect.

| Usage Condition | Typical Lifespan | Why It Lasts This Long |

|---|---|---|

| Indoor/warehouse use | 7–10 years | Minimal UV, less dirt, controlled environment |

| Occasional use (maintenance) | 5–8 years | Light wear, proper storage |

| Daily construction use | 3–5 years | Sun, dust, abrasion, heavy movement |

| Roofing or outdoor work | 2–4 years | Intense UV exposure, heat, weather |

| Neglected or poorly stored | <1–2 years | Sun, moisture, chemicals, physical abuse |

Factors That Affect Harness Lifespan

A harness doesn’t just wear out because of time—it wears out because of what you put it through. Sun, dirt, chemicals, rough storage, daily use… all of these things quietly chip away at its strength.

If you’ve ever wondered why one harness lasts years while another dies in a few months, here are the biggest factors that make or break its lifespan.

| Factor | Effect on Lifespan | Notes |

|---|---|---|

| Proper storage | Extends | Locker, gear bag, away from sun |

| Daily use | Reduces | More abrasion and stress |

| Exposure to sunlight | Reduces | UV weakens fibers |

| Exposure to chemicals/oils | Reduces | Breaks down nylon & stitching |

| Clean environment | Extends | Less contamination/dirt |

| High-quality harness | Extends | Better materials, thicker webbing |

| Cheap harness | Reduces | Lower-grade stitching & hardware |

Cleaning & Storage Effects on Harness Lifespan

How you clean and store your harness can stretch its lifespan—or destroy it without you even realizing it.

A quick rinse, the wrong soap, or tossing it in the back of a truck can shorten its life fast. Store it right, clean it gently, and you can easily add years to it. Here’s how much your habits really matter.

| Storage Method | Effect on Harness | Lifespan Impact |

|---|---|---|

| Stored in truck bed | UV + moisture damage | Lifespan reduced drastically |

| Hung near welding area | Heat & sparks damage | Severe, quick deterioration |

| Kept in PPE locker | Protected from elements | Lifespan extended |

| Stored in gear bag | Dust-free, UV-free | Consistent, long lifespan |

| Left on rooftop | Weathering, UV | Major lifespan reduction |

Quality Level vs Expected Lifespan

Not all harnesses are built the same. Some are cheap and wear out fast, while others are made with thicker webbing and tougher stitching that easily outlast the rest.

The quality you buy up front plays a huge role in how long your harness will actually survive on the job. Here’s a quick look at how quality level affects lifespan.

| Quality Level | Typical Price | Lifespan Range | Notes |

|---|---|---|---|

| Low-end | $30–$60 | 1–3 years | Thin webbing, weak stitching |

| Mid-level | $70–$150 | 3–6 years | Standard construction |

| Premium | $150–$300 | 5–10 years | Reinforced materials, better hardware |

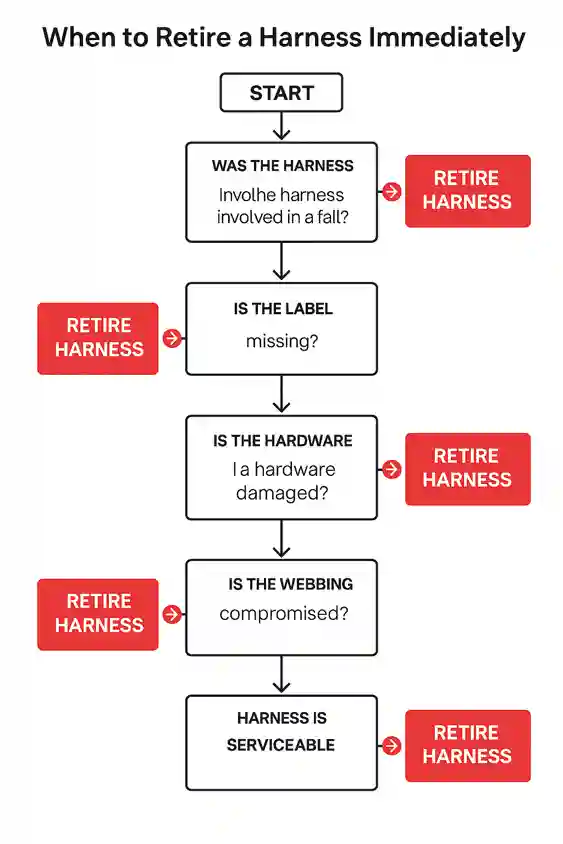

When to Retire a Harness Immediately

Some harness decisions take a little judgment—but this part doesn’t. There are moments when a harness is instantly done, no questions asked.

If you spot certain types of damage or the harness has been through the wrong situation, it’s time to pull it from service right away. Here’s when you shouldn’t take chances.

| Condition | Replace Immediately? | Why |

|---|---|---|

| Harness was in a fall | YES | Internal fibers may be damaged |

| Missing label | YES | Not compliant; unverified specs |

| Hardware damage | YES | Structural failure risk |

| Webbing damage | YES | Weakens load-bearing capacity |

| Chemical contamination | YES | Hidden fiber damage |

| Passes inspection | NO | Safe to continue using |

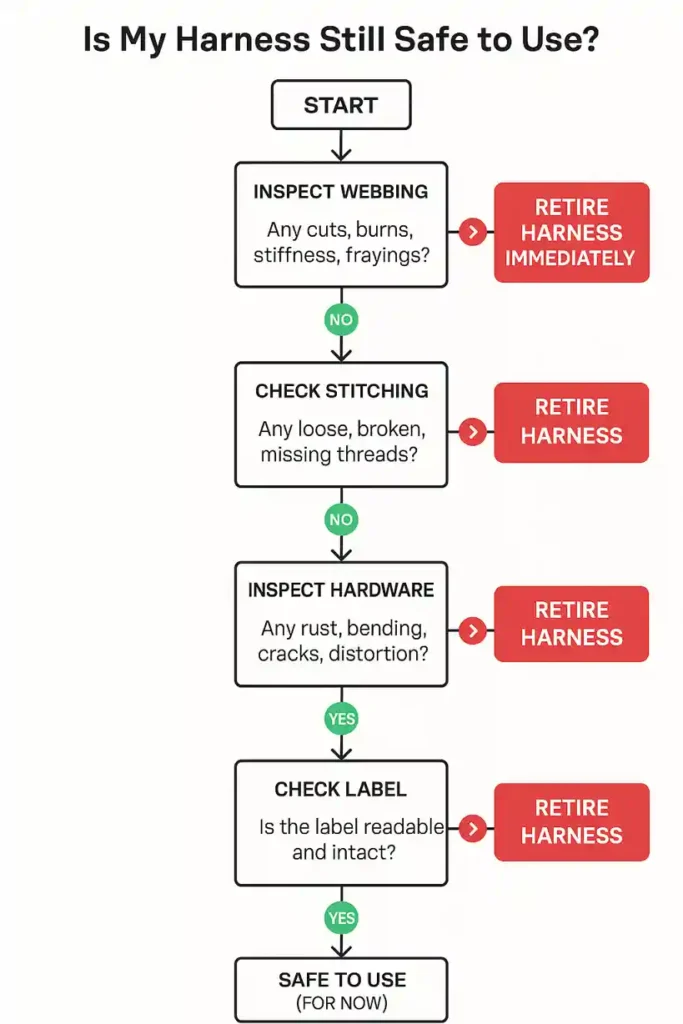

Is Harness Still Safe to Use, See This Chart

The Final Answer: How Long Does a Harness Really Last?

Here’s the truth, based on experience, inspections, and manufacturer guidelines:

If you take care of it:

5–10 years

If you use it heavily in rough conditions:

3–5 years

If you neglect it:

Less than 1–2 years

If it fails inspection:

It’s done that same minute — age doesn’t matter.

And remember:

OSHA doesn’t set a strict expiration date.

They care about condition, not age.

At the end of the day, your harness isn’t just a piece of fabric with buckles. It’s the one thing standing between you and a long fall that you might not walk away from.

Replace a harness? Sure. That’s easy.

Replace your life? Not happening.

So treat your harness right, inspect it, and when in doubt — retire it.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

View All Articles