One of the questions I hear most often during safety trainings—no matter the jobsite, the industry, or the crew—is this:

“So… who’s actually responsible for fall protection? Us or the employer?”

And honestly, I understand why people ask. I’ve been on sites where employers expect workers to bring their own harness, and others where workers decide not to tie off because “I’m just going to be up there for a minute.” I’ve also heard supervisors say, “We’ll worry about fall protection when OSHA shows up.”

All of these situations lead to confusion—and confusion leads to risk.

So if you searched this topic because you genuinely want to understand who carries the responsibility, this article breaks it down clearly, realistically, and based on what I’ve personally seen over years of working with construction and industrial teams.

Let’s get straight to the truth.

The Short Answer: OSHA Puts the Responsibility on the Employer—But Workers Have Duties Too

Legally, under OSHA standards (29 CFR 1910 for general industry, 29 CFR 1926 for construction), the employer carries the biggest responsibility. They must provide:

- A safe working environment

- Proper fall protection systems

- Fall protection equipment (like harnesses and lanyards)

- Safety training

- Supervision and enforcement

Workers, on the other hand, must:

- Use the equipment

- Follow the training

- Report hazards

- Not bypass fall protection systems

Think of it like this:

Employers provide the tools, workers use them correctly.

But that’s just the surface. Let’s go deeper.

| Responsibility Area | Employer’s Duty | Worker’s Duty |

|---|---|---|

| Provide Fall Protection Equipment | Must supply appropriate PPE (harness, lanyard, anchors) at no cost | Must use equipment properly and consistently |

| Training | Must provide OSHA-compliant fall protection training | Must attend training and follow what was learned |

| Jobsite Hazard Assessment | Must identify fall hazards and select controls | Must report new hazards noticed during work |

| Equipment Inspection | Must ensure equipment is maintained and replaced when defective | Must inspect equipment before each shift |

| Written Fall Protection Plan | Must prepare and implement (if required) | Must comply with the plan |

| Enforcement | Must enforce safe practices and discipline violators | Must follow safe practices and not engage in unsafe behavior |

| Rescue Planning | Must ensure rescue plan is in place and workers are trained | Must follow rescue procedures during an incident |

Read Related Article: Qualified vs. Competent Person in Fall Protection

When Is the Employer 100% Responsible vs Shared Responsibility?

| Situation | Responsible Party | Explanation |

|---|---|---|

| No fall protection provided at jobsite | Employer | OSHA always holds employer liable |

| Worker refuses to use provided PPE | Worker (but employer partially liable) | Employer must still enforce rules |

| No training given | Employer | Training is 100% employer responsibility |

| Worker misuses PPE despite training | Worker | If documented training + enforcement exist |

| Defective or damaged PPE | Employer | Must maintain and replace equipment |

| Worker fails pre-use inspection | Worker | Daily checks are the worker’s duty |

| Jobsite has unaddressed hazards | Employer | Hazard identification is employer obligation |

Employer Responsibilities (Based on OSHA + Real-Life Experience)

You’ve probably worked on sites that take safety seriously… and sites where fall protection is an afterthought. I’ve been on both, and the difference is massive.

Let’s walk through what employers are truly responsible for.

1. They Must Identify Fall Hazards

Before any work begins, employers are required to check the jobsite for potential fall risks, such as:

- Open edges

- Roof perimeters

- Skylights

- Floor openings

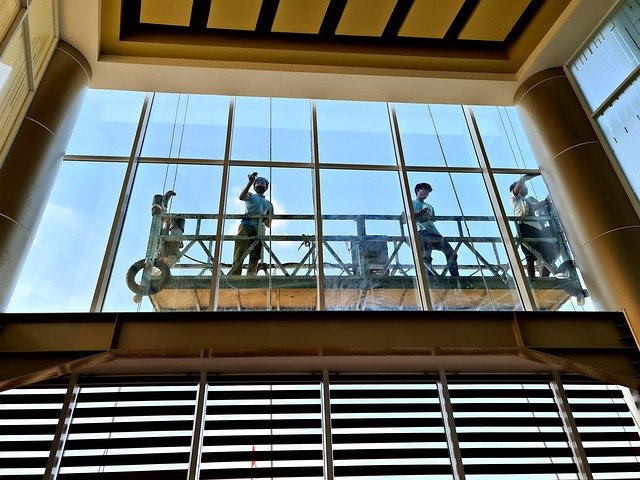

- Scaffolds

- Weak or unstable surfaces

- Slippery conditions

This is called a hazard assessment, and OSHA takes it seriously.

I once visited a renovation site where workers were moving equipment near a skylight covered with a thin plastic panel. One wrong step and someone would’ve gone straight through it. The employer had no idea the cover wasn’t load-bearing. That’s exactly why hazard assessments are non-negotiable.

2. They Must Provide Fall Protection Equipment

This part is 100% the employer’s job.

They must supply:

- Full-body harnesses

- Lanyards or SRLs

- Anchor points

- Guardrails

- Fall arrest systems

- Safety nets (when needed)

And this equipment MUST meet OSHA requirements.

I’ve seen workers show up with harnesses they bought online—cheap ones with missing labels or cracked stitching. That’s not only dangerous, it’s unacceptable. Workers should never have to buy their own gear. The employer is the one who must provide it—period.

3. They Must Provide Training (And Pay For It)

Fall protection training isn’t a “bonus”—it’s a requirement.

Employers must ensure workers are trained on:

- When fall protection is needed

- How to put on a harness

- How to connect to an anchor

- How to inspect gear

- How to recognize fall hazards

- What to do during a fall event

And training isn’t one-time. OSHA requires retraining:

- When workers show unsafe behavior

- When new equipment is introduced

- When job tasks change

- After a near miss

In my experience, the lack of retraining is one of the biggest blind spots on jobsites.

4. They Must Inspect and Maintain Equipment

Harnesses don’t last forever. Neither do lanyards, connectors, or anchor points. Employers must ensure:

- No torn or frayed straps

- No rusted hardware

- No expired equipment

- No weak anchors

- No makeshift tie-off points

I’ve inspected harnesses with burnt straps from welding sparks, and I’ve seen lanyards stored under piles of rebar where they got crushed or cut. Damaged gear is dangerous gear. And it’s the employer’s job to make sure it never gets to that point.

5. They Must Enforce the Safety Rules

This is where a lot of companies drop the ball.

Even if the employer buys the best equipment and schedules training, it doesn’t matter if they don’t enforce the rules.

Supervisors must:

- Monitor workers

- Correct unsafe behavior

- Make sure everyone ties off

- Stop the job if safety is compromised

- Document violations when necessary

If a worker doesn’t tie off and the supervisor sees it but ignores it? That becomes the employer’s responsibility.

| OSHA Standard | What It Covers | How It Applies to Employers |

|---|---|---|

| 1926.501 | Duty to have fall protection | Requires employers to protect workers at 6 ft (construction) |

| 1926.503 | Training requirements | Employers must train workers on fall hazards & equipment |

| 1926.502 | Systems & criteria | Employers must provide compliant anchors, harnesses, lanyards |

| 1910 Subpart D | Walking-working surfaces | Applies to general industry employers |

| 1910.28 | Fall protection & falling object protection | Requires employers to provide systems at 4 ft (general industry) |

Read Related Article: Who Can Give Fall Protection Training? (And Who Cannot)

Worker Responsibilities (You Play a Big Role Too)

If you’re a worker, your job is also critical—you’re the one actually doing the work at heights. You’re the last line of defense.

Here’s what OSHA expects from you:

1. Use the Equipment You’re Given

It doesn’t matter if:

- You’re only going up “for a second”

- It feels uncomfortable

- You’re in a hurry

- You’ve been doing the job for 20 years

Fall protection only works when you use it.

2. Inspect Your Gear Before Use

Workers must check:

- Harness straps

- Buckles

- D-rings

- Lanyards

- Connectors

If something looks wrong—even slightly—you report it. A single tear or crack can be the difference between life and death.

3. Follow Your Training

Improper use of fall protection is one of the leading causes of accidents—even when the equipment is available.

Examples I’ve personally seen:

- Workers tying off to handrails

- Lanyards tied in knots

- Anchors attached to weak structures

- Harnesses worn incorrectly

Training exists for a reason. Follow it.

4. Report Hazards Immediately

If you see:

- Missing guardrails

- Damaged harnesses

- Unstable ladders

- Unsafe anchor points

- Slippery surfaces

Speak up. Don’t assume someone else already knows.

Cost Responsibility Breakdown (Who Pays for What?)

| Item / Activity | Employer Pays | Worker Pays |

|---|---|---|

| Harness, lanyard, anchors | ✔ | ✘ |

| Fall protection training | ✔ | ✘ |

| Medical exams (if required) | ✔ | ✘ |

| Replacement of damaged PPE | ✔ | ✘ |

| Fines for unsafe behavior | ✘ | ✔ (disciplinary action) |

| Lost wages due to unsafe acts | ✘ | ✔ (employer not liable if worker violated rules) |

Read More About This Topic: Does OSHA Require Fall Protection Training Annually?

Who’s Really at Fault? Real Jobsite Situations Explained

To make things practical, let’s look at real-world situations I’ve personally seen—and who’s actually responsible in each case. These examples clear up a lot of confusion that workers and employers often have.

Situation 1: No Harnesses Anywhere on Site

Responsibility: Employer

You can’t expect workers to protect themselves when the proper gear doesn’t even exist. If the employer fails to provide harnesses and lanyards, that responsibility falls entirely on them.

Situation 2: Worker Has Gear but Refuses to Wear It

Responsibility: Worker

(Provided the employer has already supplied equipment, training, and enforcement.)

If a worker chooses comfort or convenience over safety—even after being properly trained—then the responsibility shifts to the worker.

Situation 3: Supervisor Watches an Untied Worker and Says Nothing

Responsibility: Employer

Supervisors represent management. If they see unsafe behavior and ignore it, the employer becomes responsible for the lack of enforcement.

Situation 4: Worker Uses Damaged or Defective Equipment Without Reporting It

Responsibility: Worker

Workers must inspect their gear before using it. If they notice damage and choose to ignore it, that’s on them.

Situation 5: New Equipment Is Introduced, but No Training Is Provided

Responsibility: Employer

If an employer brings new fall protection systems on site, they must train workers before anyone uses them. No training = employer’s fault.

Myth vs. Reality: Clearing Up Common Fall Protection Misunderstandings

A lot of confusion around fall protection comes from outdated beliefs or “word of mouth” rules that aren’t actually true. Let’s clear them up:

❌ Myth: “Fall protection is only required at 6 feet.”

✔ Reality: Height requirements vary by industry.

General industry: 4 feet

Construction: 6 feet

Scaffolds: 10 feet

Steel erection: 15 feet

Always check the standard for your specific work.

❌ Myth: “If a worker falls, it’s always their fault.”

✔ Reality: Most fall incidents trace back to employer failures—lack of equipment, lack of training, or poor enforcement.

❌ Myth: “Experienced workers don’t need safety gear.”

✔ Reality: Many fatal falls involve highly experienced workers who got too comfortable or rushed the job.

Final Thoughts

A lot of people still ask, “Who is responsible for providing fall protection?” After years of visiting jobsites, the answer is simple: safety works best when everyone does their part. Employers provide the gear and the training, and workers use that gear the right way.

At the end of the day, fall protection isn’t just about rules—it’s about making sure everyone goes home safe. So if you’re still wondering “Who is responsible?”, remember: employers supply it, workers use it, and together, you keep each other safe.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

View All Articles