If you’re looking for Fall Protection Training in California, let me tell you something upfront:

California is not like the other 49 states when it comes to safety rules. And if you’ve worked here long enough—whether you’re a roofer in Fresno, an ironworker in LA, a carpenter in San Jose, or a solar installer in Bakersfield—you already know Cal/OSHA doesn’t play around.

I’ve trained crews all over the state, from small residential roofers to big commercial contractors, and I’ve seen the same thing every time: workers know fall protection is important… but California’s rules feel like a different world.

So in this guide, I’m going to break down how Fall Protection Training actually works, what makes it different, what Cal/OSHA expects, what specific industries need to know, and how you (or your crew) can stay compliant without losing your mind.

Let’s jump in.

Why Fall Protection Training Is So Important in California

| Category | Federal OSHA (29 CFR) | Cal/OSHA Title 8 (California) |

| Regulation Reference | • 29 CFR 1926 Subpart M (Construction) • 29 CFR 1910 (General Industry) | • Title 8, CCR (Multiple sections) • Much more detailed and state-specific • Includes roofing, steel erection, scaffolds, telecom, etc. |

| Trigger Height | • 6 ft – Construction • 4 ft – General Industry • 10 ft – Scaffolds • 15 ft – Steel erection (connectors) | • 6 ft – Construction (*same as OSHA*) • 4 ft – General Industry • 7½ ft – Unguarded work surfaces (Title 8 is stricter) • 15 ft connecting but 30 ft max exposure for ironworkers • Additional heights for roofers, framing, and telecom |

| Roofing Requirements | • Standard guardrails, nets, PFAS • Less specific residential-roofing language | • Title 8 §1730 specifically regulates roofers • Stricter rules for: – Steep roofs – Controlled Access Zones – Tile & metal roof hazards • California inspects roofing work far more frequently |

| Anchorage Requirements | • 5,000 lbs per person • Or designed by qualified person • OSHA does not emphasize manufacturer instructions as strongly | • 5,000 lbs per employee • Must follow **manufacturer requirements strictly** • Cal/OSHA cites improper temporary-anchor installation often • State inspectors frequently ask for anchor documentation |

| Equipment Inspection | • “Regular inspection” required • Not always enforced consistently | • Daily inspections of harness, lanyards, SRLs • Weather-related inspection (sun damage, heat, corrosion) is emphasized • Cal/OSHA inspectors often ask workers to demonstrate inspection |

| Training Requirements | • Classroom or on-the-job • No explicit hands-on requirement • Refresher required when unsafe behavior is observed | • **Hands-on training required** (demonstrated competency) • Must cover California-specific hazards • Retraining required more frequently • Documentation must show hands-on evaluation • Inspectors often interview workers on the spot |

| Rescue Plan Requirements | • Encouraged but not strictly required in all situations • 911 sometimes assumed as adequate | • **Mandatory written rescue plan** for fall arrest systems • Must include prompt rescue, equipment, and assigned duties • 911 alone is **not compliant** |

| Enforcement & Penalties | • Lower penalty averages • Fewer field inspections than California | • **Highest penalty levels in the country** • More aggressive inspector activity • Roofing & solar projects frequently targeted • Repeat violations can trigger immediate job shutdown |

| Industry-Specific Rules | • Steel erection (Subpart R) • Nonspecific for roofers, solar installers, framers | • Roofing: §1730 • Steel erection: §1710 • Scaffolds: §1637 • Agriculture: §3456 • Telecom: §8615 • Solar installation (interpreted under multiple Title 8 sections) |

| Climate & Environmental Factors | • Not directly addressed • No heat-specific requirements | • Sun/UV damage strongly emphasized • Heat illness prevention standard applies • Hot weather accelerates degradation of PFAS components • Inspectors expect workers to identify heat-related equipment damage |

I’ve been on sites where workers avoided serious injuries because they remembered something they learned in training.

One guy in Riverside came up to me months later and said:

“I was about to clip to a vent pipe, remembered your story, checked it—and sure enough, the thing wasn’t even attached right.”

That’s why this stuff matters.

California:

- Has more inspections

- Has higher fines

- Has more roofers and solar workers than any other state

- Has intense weather that wears out gear

- Has some of the strictest rules in the country

Training is not something you skip or rush.

Your life—and your workers’ lives—literally depend on it.

Types of Fall Protection Allowed Under Cal/OSHA

| Type of Protection | Description | When Allowed (California Rules) | Title 8 Section | Common Mistakes in CA Jobsites |

| Personal Fall Arrest System (PFAS) | Harness, lanyard/SRL, and anchor designed to arrest a fall. | • Above 6 ft (construction) or 4 ft (general industry) • Leading-edge work • Roof work where guardrails aren’t feasible • Steel erection with 100% tie-off | §1670 | • Clipping to pipes/vents/rebar • Loose harness straps • Using sun-damaged lanyards or SRLs • Swing hazards ignored |

| Guardrails | Barrier system preventing workers from reaching the fall edge. | • Platforms, mezzanines, open edges • Roof perimeters (flat roofs) • Scaffolds (top rail, midrail, toeboards) | §1620–1621 | • Missing midrails • Incorrect height (not 42” top rail) • Not designed to withstand 200 lbs force |

| Controlled Access Zones (CAZ) | Restricted area where certain roofing work can occur without conventional fall protection. | • Residential roofing • Only for specific tasks (sheathing, some roofing phases) • Must be controlled by a competent person | §1671.1 / §1730 | • Used for tasks not allowed • No monitoring or enforcement • Boundary lines not properly marked |

| Safety Nets | Netting installed below a work surface to catch a falling worker. | • Bridge work • High-rise or commercial construction • When PFAS or guardrails are infeasible | §1671 | • Nets too far below workers • Nets not tested every 6 months • Holes or damage unnoticed due to lack of inspections |

| Positioning Systems (Work-Positioning) | System that holds workers in place while allowing both hands free (not designed to arrest a fall). | • Tower work • Rebar installation • Climbing operations • Only when a fall of more than 2 ft is prevented | §1670 / §3410 | • Workers use them as fall arrest • Lanyards too long • Anchors not rated for positioning systems |

| Warning Line Systems (Roofing Only) | Visual perimeter marker used in roofing work to alert workers before reaching an edge. | • Only allowed for roofing • Only on low-slope roofs (≤ 4:12 pitch) • Must be combined with a fall protection plan | §1671.1 / §1730 | • Used alone as fall protection • Set too close to the roof edge • Not maintained or monitored |

Why California Fall Protection Rules Are Stricter Than Federal OSHA

Most people don’t realize this until they get cited, but California doesn’t follow federal OSHA’s rulebook.

We follow Cal/OSHA Title 8, which is basically OSHA turned up to 11.

Here’s the short version:

California Trigger Heights (These surprise a LOT of new workers)

- 4 feet – General industry

- 6 feet – Construction

- 15 feet – Ironworkers during initial connecting

- Zero freefall allowed in many situations unless you’re fully tied off

- Roofers have their own section (Title 8 §1730), which inspectors love to use

Compared to federal OSHA, which usually starts at 6 feet, Cal/OSHA is basically saying:

“If you can fall and get hurt… we want you tied off.”

And trust me, they enforce it. I’ve seen inspectors walk onto a site, look up once, and shut the whole operation down within 30 seconds.

This is why California fall protection training MUST be state-specific.

A generic “OSHA 1926 Subpart M” course won’t save you here.

This is How the Training is Done

| Training Step | What Happens | Cal/OSHA Requirement | Why This Step Matters |

| 1. Review Training Materials | Trainer introduces regulations, hazards, equipment, and California-specific rules using slides, manuals, and videos. | Must cover Title 8 requirements, hazard recognition, equipment types, and fall protection systems. | Workers understand *what* fall hazards exist and *why* fall protection is required in California. |

| 2. Classroom Instruction | Trainer explains rules, demonstrates concepts, and answers questions using real-world scenarios. | Cal/OSHA requires formal instruction that includes state-specific fall protection procedures. | Provides the knowledge foundation workers need before touching equipment. |

| 3. Demonstrate Skills & Equipment | Trainer shows how to inspect harnesses, attach lanyards, set anchors, and use SRLs and lifelines safely. | Hands-on demonstration is required; workers must *see* proper techniques. | Visual learning makes workers more confident and reduces misuse of equipment. |

| 4. Hands-On Practice | Workers wear harnesses, set up anchors, inspect equipment, and simulate tying off under supervision. | Cal/OSHA requires “demonstrated competency”—workers must *perform* each task. | Hands-on practice is where most unsafe behavior gets corrected early. |

| 5. Competency Evaluation | Trainer tests workers via observation, quizzes, or performance checklists. | Workers must show they understand and can safely perform fall protection tasks before being approved. | Ensures every worker is qualified before stepping foot on a roof, structure, or elevated area. |

| 6. Documentation & Certificates | Trainer completes rosters, hands-on checklists, evaluation forms, and issues a certificate of completion. | Cal/OSHA requires complete training records specifying hands-on demonstration and trainer qualifications. | Proper documentation protects the employer during inspections and citations. |

Training Providers in the State

| # | Provider Name | Location / Contact Info | What They Offer / Notes |

|---|---|---|---|

| 1 | All Purpose Safety Training Solutions (APSTS) | Phone: (888) 978-2713 | Cal/OSHA-focused safety training including fall protection; statewide coverage |

| 2 | CAI Safety Systems, Inc. | Ontario, CA — offers Competent Person & Authorized Person training. | Hands-on + classroom fall protection training; ANSI/OSHA-aligned courses. |

| 3 | OSHA Training Services Inc. | Stockton, CA + on-site & online options | Provides OSHA/Cal-OSHA courses including fall protection, 10-hr/30-hr, confined space, etc. |

| 4 | Title 8 Builders | 28220 Avenue Crocker Unit 404, Valencia, CA 91355 — Phone: 661-713-8060 | Offers “Authorized User” and “Competent Person” fall protection courses (hands-on + classroom), per Cal/OSHA Title 8. |

| 5 | Hazmat School | Online / remote — California-wide | Offers a 1-hour California Fall Protection Course (online), covering fall hazards, PPE, anchor use, etc. |

What Fall Protection Training in California Must Cover (If You Want to Stay Compliant)

A legit California fall protection course should cover the basics—sure—but Cal/OSHA requires more depth.

Here’s what I cover when I train crews, and it lines up perfectly with Title 8 requirements.

1. Hazard Recognition

Not just “don’t fall.”

In California, we deal with:

- Skylights

- Sun-damaged anchor points

- Spanish-tile roofs

- Steep pitches

- Temporary anchors that bake in 100°F heat

- Guardrails that warp from the sun

These are real issues I’ve seen over and over.

2. Proper Harness Use (The Hands-On Section Cal/OSHA Loves)

You’d be shocked how many California workers wear a harness like it’s a loose backpack.

We cover:

- Adjusting the chest strap so it won’t choke you

- Leg straps tight enough without cutting off circulation

- D-ring placement

- Heat-damage inspection (super important in CA)

3. Anchor Points – Title 8 Is Very Specific

California says:

- 5,000 lbs per worker, OR

- An engineered anchor designed for the fall arrest system

- Temporary anchors must be used per manufacturer’s instructions (Title 8 cares about this!)

4. Using Lanyards, SRLs, and Vertical Lifelines

California loves SRLs (self-retracting lifelines) because they reduce freefall.

But workers must be trained to:

- Avoid swing hazards

- Understand clearance

- Set up systems on steep roofs

- Prevent edge damage

5. Guardrails and Hole Covers

Cal/OSHA requires:

- 42” top rail

- Midrail

- Toeboards in many conditions

- Covers marked “HOLE—DO NOT REMOVE”

Ask any California roofer—they’ve failed an inspection over guardrails more times than they’d like to admit.

6. Fall Rescue Requirements

This is a big California difference.

Cal/OSHA expects a written rescue plan, not just “we’ll call 911.”

Training MUST include:

- Self-rescue basics

- Assisted rescue

- Suspension trauma awareness

The Hands-On Portion: Where California Gets Serious

A lot of people think you can just sit through an online course and call it a day.

Nope.

California requires demonstrated competency, which means hands-on practice.

If training doesn’t include a practical component, you’re not Cal/OSHA compliant—period.

During hands-on sessions, workers must demonstrate:

- Harness donning and adjustment

- Equipment inspections

- Finding and evaluating real anchor points

- Properly using SRLs, ropes, and lanyards

- Connecting to vertical and horizontal lifelines

- Checking equipment labels

I’ve had Cal/OSHA inspectors ask workers right on the spot:

“Show me how you inspect your harness.”

If your workers freeze, that’s a citation waiting to happen.

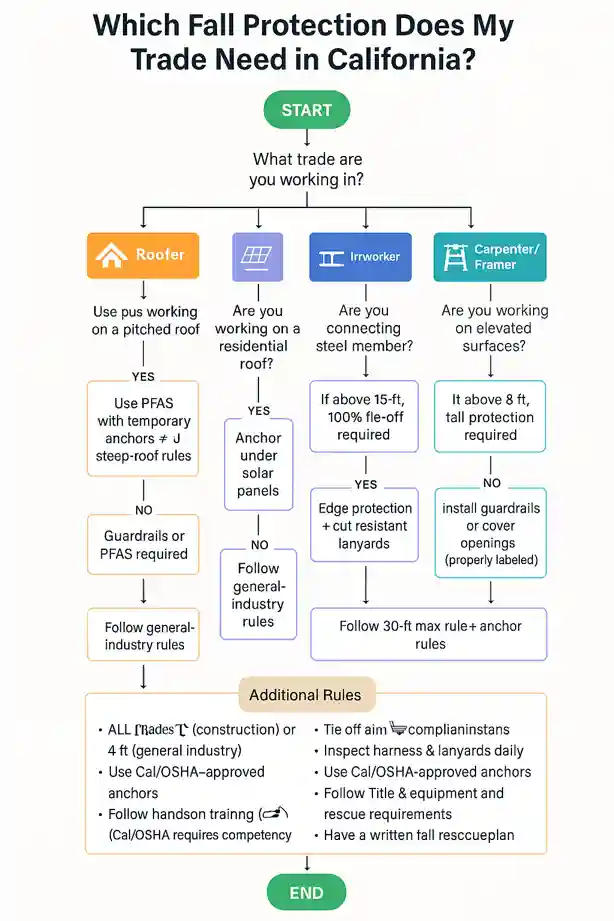

California-Specific Industries: What You Need to Know

Different trades get hit by inspectors for different reasons. Let me break down the real-world stuff I’ve seen.

| Industry | Why Cal/OSHA Targets This Trade | Training Topics Required (California-Specific) |

| Roofers | • Most common source of fall injuries • High inspection rates in residential roofing • Frequent wind, heat, and steep-roof hazards | • Temporary anchor installation & removal • Controlled Access Zones (CAZs) • Tile/metal roof slip hazards • Effects of California heat on webbing & stitching • Working on 2-story sloped homes • Handling Santa Ana winds safely |

| Solar Installers | • Solar boom = more roof work • Inspectors frequently check solar projects • High risk from panel edges and improper anchors | • Steep roof fall protection • Use of anchors beneath solar panels • Ladder setup & use per Title 8 • Preventing panel-edge cuts on ropes/lanyards • Proper SRL use (swing hazards, clearance, edge exposure) |

| Ironworkers | • Cal/OSHA applies stricter rules than federal OSHA • Connecting and decking phases are high-risk • Leading-edge work prone to fatal falls | • 15-ft rule for connecting • 30-ft max exposure without 100% tie-off • Column-climbing fall protection rules • Decking, bridging & leading-edge hazards • SRL vs lanyard use during steel erection |

| Carpenters & Framers | • Many falls occur in early building stages • Belief in “quick tasks” leads to violations • Platform and opening hazards are common | • Guardrail installation standards • Temporary wooden anchor points • Platform, scaffold & elevated surface rules • Through-floor hole protection & labels • Proper tie-off during wall framing & truss work |

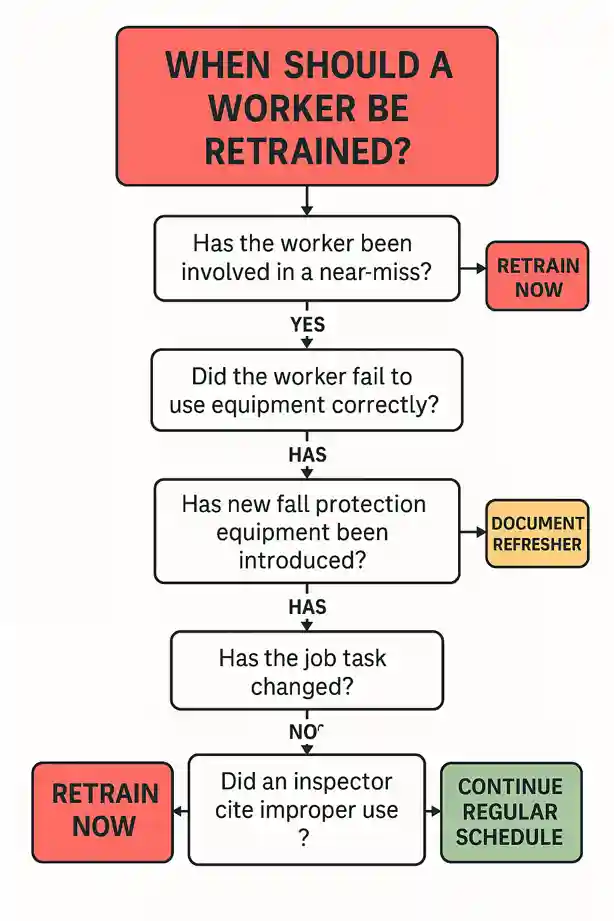

How Often Do You Need Fall Protection Training in California?

Contrary to what some think, Cal/OSHA does not set a strict “expiration date” like 1 year or 2 years.

BUT retraining is required:

- After a near-miss

- After unsafe behavior

- When a worker forgets or performs incorrectly

- When new equipment is introduced

- After rule changes

- If the worker’s job duties change

Most California contractors do annual refresher training because inspectors ask for recent documentation.

Training Records: What Cal/OSHA Wants to See

A simple sign-in sheet isn’t enough.

Your Fall Protection Training in California should include:

- Worker’s full name

- Trainer’s name and qualifications

- Date of training

- Detailed topics covered

- Hands-on activities completed

- Equipment used during training

- Evaluation or skills demonstration record

- Worker signatures

I’ve had inspectors walk up and say:

“Show me proof this worker was trained specifically for this equipment.”

If the training was too generic, it won’t count.

Final Thoughts: Why Fall Protection Training in California Isn’t Optional—It’s Survival

At the end of the day, working at heights in California means playing by some of the toughest safety rules in the country—and honestly, it’s for a good reason.

Cal/OSHA has seen every type of fall accident imaginable, and their standards reflect real-world hazards that happen on California jobsites every single day: tile roofs that crumble under your boots, steel beams slick with morning fog, SRLs damaged by the relentless sun, and winds that can knock a skilled roofer off balance in seconds.

That’s why proper fall protection training isn’t just a box to check—it’s what keeps you, your crew, and your company out of trouble and out of the emergency room. When workers know how to select the right anchor, properly fit a harness, recognize rooftop hazards, use an SRL correctly, and follow Title 8 requirements, the entire jobsite becomes safer and more productive.

California inspectors expect workers to be trained, competent, and able to prove it. And honestly? They’re right. Because once you’ve seen what a preventable fall can do, you realize that training isn’t paperwork—it’s protection.

So whether you’re roofing in Fresno, installing solar in Bakersfield, framing in San Diego, or connecting steel in Los Angeles, remember this:

The best fall protection system in the world won’t save you unless you know how to use it.

Training is where safety starts—and where California draws the line.

Stay trained. Stay tied off. Stay alive.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

View All Articles