If you’re working in Colorado—whether you’re climbing roofs in Denver, doing HVAC on a snowy rooftop in Colorado Springs, or framing a house in Fort Collins—here’s one truth you can’t ignore:

Falls don’t care how experienced you are.

New guys fall. Old guys fall. People who “know what they’re doing” fall.

And in this state, where weather changes in five minutes and jobsites aren’t always flat, fall protection training is something you don’t skip.

I’ve worked with crews that treat fall protection like just another OSHA requirement… and I’ve worked with crews who truly understand how fast a normal day can turn into a hospital visit. Trust me, the second group sleeps a lot better.

So let me walk you through what Fall Protection Training in Colorado really means, what it covers, what you should expect, and how to pick good training—not the cheap stuff that checks a box and teaches you nothing.

Why Fall Protection Training Matters a Little More in Colorado

First, let’s acknowledge the elephant in the room:

Colorado job sites have extra variables.

Wind. Snow. Sloped roofs. High-altitude fatigue. Sudden weather swings.

A calm morning in Loveland can turn into 40 mph gusts by noon. Snow melts, refreezes, and suddenly the plywood you’re standing on becomes a skating rink. Even scaffold planks get slick at elevation.

So yes—OSHA’s fall protection rules apply everywhere, but in Colorado, they hit harder because nature plays rough.

And that’s exactly why fall protection training isn’t just “something to get the card.” It’s something that can literally save your life when the weather decides to surprise you.

What Does OSHA Require?

| OSHA Requirement | Standard / Regulation | What It Means (Plain English) |

|---|---|---|

| Employees must be trained before exposure to fall hazards | 1926.503(a)(1), 1910.30(a) | Training is required before workers use ladders, roofs, lifts, scaffolds, or any elevated surface. |

| Training must be conducted by a Competent Person | 1926.503(a)(2) | The trainer must understand fall hazards and have the authority to correct unsafe behavior — not just read slides. |

| Workers must be trained to recognize fall hazards | 1926.503(a)(2)(i) | Hazards include edges, holes, skylights, slick surfaces, scaffolds, and unstable structures. |

| Workers must learn how to use fall protection systems properly | 1926.503(a)(2)(i–ii) | How to use harnesses, PFAS, guardrails, safety nets, restraint systems, and positioning equipment. |

| Training must cover equipment inspection & maintenance | 1926.503(a)(2)(iii) | Inspect harnesses, lanyards, SRLs, connectors, anchors, labels, and lifelines before use. |

| Training must cover installing, assembling, disassembling fall protection systems | 1926.503(a)(2)(iv) | Workers must know how to safely set anchors, lifelines, guardrails, and other systems. |

| Understand system limitations | 1926.503(a)(2)(v) | Clearance distance, swing fall, capacity limits, and free-fall restrictions must be explained. |

| Role in safety-monitoring systems | 1926.503(a)(2)(vi) | Required for roofing jobs that use warning lines or monitors instead of full protection. |

| Correct procedures for handling tools & materials at height | 1926.503(a)(2)(vii) | Prevents tripping hazards, dropped tools, and unsafe movement near edges. |

| Fall hazard control methods | 1926.503(a)(2) | Hierarchy of controls: eliminate, guard, protect. |

| Training must be understandable to the worker (language requirement) | 1910.30(a)(5) | Training must be given in the worker’s language (e.g., English, Spanish, Tagalog). |

| Documentation (written certification) required | 1926.503(b)(1) | Must include: worker’s name, date, trainer signature, topics covered. |

| Retraining required under specific conditions | 1926.503(c), 1910.30(c) | Retrain when: new equipment is introduced, new hazards appear, worksite changes, or the worker misuses equipment. |

| Employer must verify competency | 1910.30(d) | Workers must demonstrate they can use fall protection correctly — not just attend training. |

| Ladder-specific training | 1910.23 + 1910.30 | Proper ladder setup, angle, climbing, securing, and when fall protection is needed. |

| Scaffold-specific training | 1926.454 | Scaffold load limits, access, electrical hazards, PFAS on scaffolds. |

| Aerial lift training requirements | 1926.453 | Tie-off rules, safe driving, pre-use inspection, fall arrest in boom lifts. |

Who Actually Needs Fall Protection Training in Colorado? (Spoiler: More People Than You Think)

People usually think fall protection only applies to roofers and ironworkers. Nope. If your job involves ANYTHING off the ground—even six feet—OSHA expects you to have fall protection training. That includes:

| Worker Category | Typical Tasks at Height | OSHA Trigger Height | Why Training Is Required |

|---|---|---|---|

| Roofers | Working on edges, sloped roofs, leading edges | 6 ft (Construction) | High fall exposure, unstable surfaces, Colorado wind/snow risks |

| Solar Installers | Installing panels on pitched roofs | 6 ft (Construction) | Frequent roof movement, tools create trip hazards |

| Carpenters & Framers | Trusses, framing walls, platforms | 6 ft (Construction) | Leading edges + unguarded openings |

| Ironworkers | Steel erection, decking | 6 ft (Construction) | Major fall heights; specialized fall systems required |

| Construction Laborers | General site work, hauling materials | 6 ft (Construction) | Often near openings, edges, scaffolds |

| Warehouse Workers | Mezzanines, ladders, elevated platforms | 4 ft (General Industry) | Lower fall threshold; frequent ladder use |

| Telecom Workers | Working on towers, poles, roofs | Any height | Climbing systems required; extreme exposure |

| HVAC Technicians | Rooftop units, ladder work | 4–6 ft | Rooftop conditions + equipment handling increases risk |

| Painters | Ladders, scaffolds, lifts | 4–6 ft | Frequent ladder movement and tight spaces |

| Maintenance Workers | Repairs on roofs, ceilings, structures | 4–6 ft | Unpredictable hazards + varied surfaces |

| Anyone Using Ladders Regularly | Climbing, carrying tools, repairs | No height minimum for ladder misuse | Most fall injuries start from improper ladder use |

| Aerial Lift Operators | Boom lift, scissor lift tasks | Any height | OSHA requires tie-off in boom lifts |

| Scaffold Users | Working on multi-level platforms | 10 ft (Construction) | Guardrails or PFAS required |

Anyone who uses a ladder regularly Colorado doesn’t change the federal rules—you still follow OSHA 1910 (general industry) and 1926 (construction). But Colorado jobsites make those rules even more necessary. If you work at heights, or near edges, or around skylights, or on scaffolds, or on aerial lifts—you need this training. Period.

What the Training Must Cover — Key Topics & Knowledge (Based on OSHA / Best Practice)

Here’s what a comprehensive fall protection training program should include (and what you should expect when you sign up for one):

| Topic | Description / Why It Matters |

|---|---|

| Recognizing Fall Hazards | Teach workers to identify where falls could happen: unprotected edges/rooflines, open floor holes, scaffolding, ladders, elevated platforms, floor openings, unguarded sides, dangerous equipment below, etc. |

| Understanding Applicable Standards & Regulations | Cover which OSHA (or state) rules apply depending on industry (construction vs general), and what legal obligations employers + workers have. |

| Fall Protection Systems — Types & When to Use Them | Explain the “big three” (guardrail systems, safety net systems, personal fall arrest systems) plus other options like warning-line systems, safety monitoring, controlled access zones. |

| Correct Use, Inspection, Maintenance & Storage of Equipment | Training must include how to properly put on harnesses, anchor, tie off, inspect equipment before use, maintain and store gear. |

| Procedures for Erecting & Setting Up Protection Systems | For workplaces using guardrails, nets, scaffolds, or other systems — how to erect, maintain, inspect, disassemble safely. |

| Safe Work Practices & Methods to Minimize Hazards | Strategies beyond just “wearing harnesses” — e.g. housekeeping (keep floor dry/clean), guardrails around opening, planning the work to reduce risk, etc. |

| Rescue Planning & Emergency Procedures | What to do if a fall happens — you need a plan especially if using fall-arrest systems. Some training programs include rescue-operations training. |

| Worker Responsibilities & Employer Responsibilities | Make clear who does what: workers must follow procedures, inspect gear; employers must provide gear, training, hazard-free conditions, and ensure compliance. |

| When & How Often to Retrain / Certification & Documentation | Training must be by a “competent person,” and must be certified. Retraining is required when workplace changes, new equipment, or if worker’s skill is inadequate. |

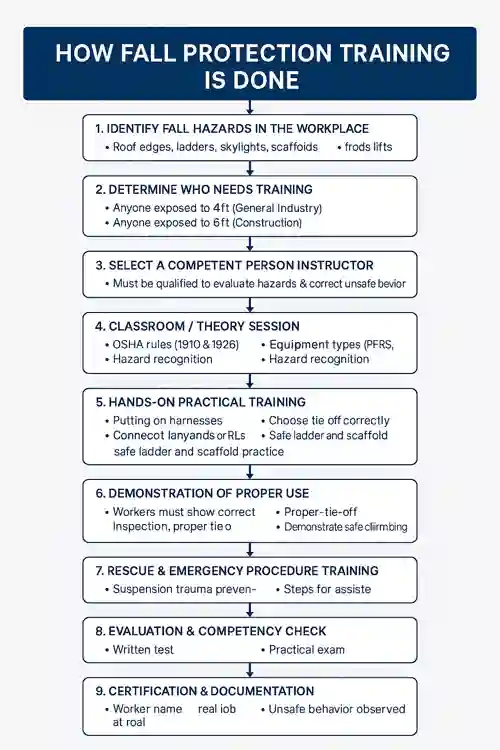

This is How the Training is Done

What to Look for in a Good Fall Protection Training Course

| Topic | Description / Why It Matters |

|---|---|

| Recognizing Fall Hazards | Teach workers to identify where falls could happen: unprotected edges/rooflines, open floor holes, scaffolding, ladders, elevated platforms, floor openings, unguarded sides, dangerous equipment below, etc. |

| Understanding Applicable Standards & Regulations | Cover which OSHA (or state) rules apply depending on industry (construction vs general), and what legal obligations employers + workers have. |

| Fall Protection Systems — Types & When to Use Them | Explain the “big three” (guardrail systems, safety net systems, personal fall arrest systems) plus other options like warning-line systems, safety monitoring, controlled access zones. |

| Correct Use, Inspection, Maintenance & Storage of Equipment | Training must include how to properly put on harnesses, anchor, tie off, inspect equipment before use, maintain and store gear. |

| Procedures for Erecting & Setting Up Protection Systems | For workplaces using guardrails, nets, scaffolds, or other systems — how to erect, maintain, inspect, disassemble safely. |

| Safe Work Practices & Methods to Minimize Hazards | Strategies beyond just “wearing harnesses” — e.g. housekeeping (keep floor dry/clean), guardrails around opening, planning the work to reduce risk, etc. |

| Rescue Planning & Emergency Procedures | What to do if a fall happens — you need a plan especially if using fall-arrest systems. Some training programs include rescue-operations training. (University of Colorado Boulder) |

| Worker Responsibilities & Employer Responsibilities | Make clear who does what: workers must follow procedures, inspect gear; employers must provide gear, training, hazard-free conditions, and ensure compliance. |

| When & How Often to Retrain / Certification & Documentation | Training must be by a “competent person,” and must be certified. Retraining is required when workplace changes, new equipment, or if worker’s skill is inadequate. |

Here are the Training Providers in the State of Colorado

| Provider Name | Address / City (or Region) | Contact Info / Notes |

|---|---|---|

| Colorado Safety Supply Company | 3700 East 41st Ave, Denver, CO 80216 (coloradosafetysupply.com) | Phone: (303) 537-5832 |

| WACO Scaffolding and Equipment Company | 3345 Drennan Industrial Loop S, Colorado Springs, CO 80910; Denver location: 121 E 58th Ave, Denver, CO 80216 (wacoscaffoldingco.com) | Colorado Springs: (719) 528-8484 / Denver: (303) 297-9226 |

| True Safety Services | 3050 67th Ave. STE 101, Greeley, CO 80634; 7007 E. 88th Ave., Henderson, CO 80640 (truesafetyservices.com) | Call/Text: (970) 534-2530 |

| Elevated Safety | Arvada, CO 80002 (course location) (elevatedsafety.com) | Contact via website |

| TriVent Safety & Training | 1499 W 120th Ave #110, Westminster, CO 80234 (triventsc.com) | Contact via website |

| EDGE Fall Protection | Serves Aurora & Metro Denver (edgefallprotection.com) | Contact via website |

How Much Does the Training Cost?

The cost of fall-protection training in Colorado (and in the U.S. generally) varies widely depending on the provider, the format (online vs in-person vs hands-on), and how in-depth the training is. Here’s a rough breakdown from public data to give you a sense of what you might pay.

| Type of Training / Course | Typical Price Range (USD) / Notes |

|---|---|

| Basic online awareness / certificate course (short, 1–2 hours) | ~$25–$50 |

| Competent-person or more thorough online fall-protection course | ~$50–$60 |

| In-person / classroom-based or mixed (theory + practical) training | ~$150–$350 |

| More advanced or specialized courses (e.g. “competent person,” rescue planning, on-site group training, tower/climb work, etc.) | ~$300–$800 (or more, depending on depth & scope) |

| On-site group training for a crew or employer (bulk / multiple people) | Can run $500–$2,000+ per session, depending on number of participants, equipment provided, and whether hands-on/practical portions included |

Why Costs Vary — What You Should Watch Out For

The wide range of prices comes down to a few key factors:

- Level of training: A basic “certificate” (just theory or online slides) is cheap. A full “competent person + hands-on + practical + rescue + equipment-use” course costs more because of instructor time, equipment, and safety oversight.

- Format: Online courses tend to be cheaper, but many employers — especially for jobs at height — require in-person, hands-on training. Practical training costs more.

- Group vs. individual: Training a single individual is cheaper per head. Training a group or crew (with equipment and on-site demo) usually costs more overall, but sometimes represents lower per-person cost.

- Specialty/Scope: If your work involves towers, lifts, scaffolds, complex anchor systems — or if the course includes advanced rescue and compliance training — expect higher cost.

- Location / Travel / Equipment: If a trainer must travel to your site (or if you need specialized equipment for demo), cost tends to rise.

What This Means for You (If You Are Hiring / Planning Work in Colorado)

- If you just need a basic “fall protection awareness” certificate (for light work, ladder use, occasional roof access) — going with a basic online course (≈ $25–$60) may be enough.

- If you’re doing construction, roofing, roof-access, scaffold use, work at heights — especially in Colorado’s weather/terrain — go for a full, in-person or competent-person course. Budget around $150–$350 per person as a starting point, possibly more if specialized.

- If you manage a crew / multiple workers, or plan regular elevated-work operations (e.g. tower, roof, scaffolding, maintenance, etc.), consider group training or on-site training — even if it’s more expensive upfront — because it ensures proper equipment use, rescue coverage, and group compliance.

- Always ask the provider what’s included: theory, hands-on, certification, rescue training, anchor inspections, documentation. Cheaper isn’t always better — incomplete training may leave gaps in safety or compliance.

Final Thoughts

At the end of the day, fall protection training isn’t just a legal requirement — it’s a lifeline. Working at heights in this state comes with its own unique set of challenges: sudden wind gusts, icy rooftops, steep pitches, and fast-changing weather. Even the most experienced workers can find themselves one bad step or one missed hazard away from a serious fall.

Proper training gives you more than a certificate.

It gives you the confidence to recognize hazards before they become problems… the skills to use your gear the right way… and the awareness to make decisions that keep you and your crew safe.

Whether you’re a roofer in Denver, a solar installer in Fort Collins, an HVAC tech in Colorado Springs, or a general contractor anywhere in between, fall protection training is one thing you can never afford to skip. Safety isn’t just about compliance — it’s about going home at the end of every shift.

Colorado jobsites can be unpredictable, but your safety doesn’t have to be. Invest in real training, ask questions, practice what you learn, and never take shortcuts when lives are on the line.

Because in this line of work, fall protection isn’t just part of the job — it’s what keeps you alive.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

View All Articles