If you work in Connecticut—construction, maintenance, warehousing, utilities, telecom, or even a small roofing crew—you’ve probably heard someone say, “Yeah, we know the OSHA rules.”

But then you look around and notice:

- guys standing on the edge of a flat roof with no guardrail,

- a ladder tied off with a bungee cord someone found in the truck,

- a harness hanging in the gang box that hasn’t been inspected in three years,

- or a foreman yelling, “Just hurry up, it’s only a quick job!”

Let me tell you something as someone who’s been on Connecticut sites for a long time: fall hazards don’t care if the job is “quick.” And OSHA definitely doesn’t care. If they catch you, especially in CT construction, you’re going to feel it in your wallet.

This is why fall protection training in Connecticut is a must—not optional, not “we’ll do it later,” but a real requirement backed by federal OSHA and, in certain industries, state-level rules.

Let’s break it all down.

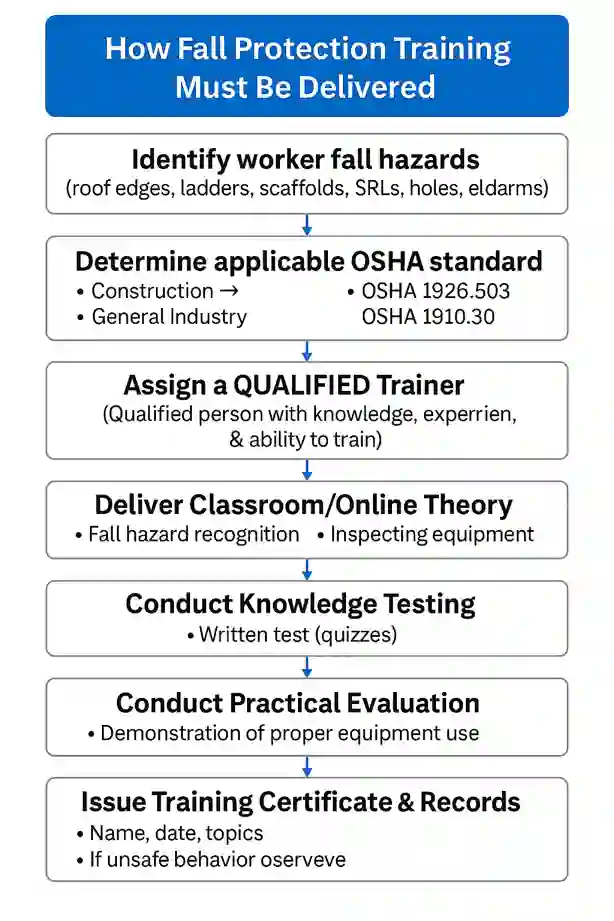

How Fall Protection Training Must Be Delivered

What Training Must Cover

| Training Topic | Required? | Description |

|---|---|---|

| Hazard Recognition | ✔ | Identify edges, holes, weak surfaces, skylights |

| Harness & Equipment Use | ✔ | How to wear, adjust, and connect harness components |

| Lanyards & SRLs | ✔ | When to use each, how to inspect |

| Anchor Points | ✔ | Identifying certified vs. unsafe anchors |

| Ladder Safety | ✔ (construction + GI) | Proper setup, angle, inspection |

| Scaffold Safety | ✔ (construction) | Guardrails, planking, access requirements |

| Rescue Procedures | ✔ | How to retrieve a fallen worker |

| Equipment Inspection | ✔ | Stitching, webbing, labels, hardware |

| Fall Distance Calculations | Recommended | Total fall clearance, swing fall |

Paperwork Required

| Documentation Type | Required? | Reason |

|---|---|---|

| Training Certificate | ✔ | Proof during audit/inspection |

| Attendance Sheet | ✔ | Verifies who attended |

| Trainer Qualifications | ✔ | OSHA requires a “qualified person” |

| Written Test Results | Recommended | Shows retention of knowledge |

| Hands-on Demonstration Log | ✔ | Proves practical skills were evaluated |

| Training Materials | Recommended | Slides, manuals, handouts |

What Counts as “Proof of Training” in Connecticut?

Here’s what you (or your workers) must have:

✔ Training Certificate

Must show:

- worker name

- employer name

- trainer’s name + qualifications

- date of training

- topics covered

- signature of trainer

✔ Sign-in Sheet (attendance roster)

Auditors LOVE this.

✔ Written Training Materials

Slides, pamphlets, handouts—anything that proves the topics were taught.

✔ Practical Demonstration Records

Especially important for:

- ladders

- SRLs

- harness donning

- anchorage use

Written tests plus hands-on practice are the gold standard.

Fall Protection Training Providers in Connecticut

| Provider | Address | Phone | Notes |

|---|---|---|---|

| Hettrick, Cyr & Associates, Inc. | 59 Sycamore Street, Glastonbury, CT 06033 | (860) 652-9997 • (888) 805-0300 | CT safety consulting firm offering OSHA-based Fall Protection Competent Person training. |

| Connecticut Training & Consulting Institute (CTTCI) | 1116 Portland Cobalt Rd, Portland, CT 06480 | (860) 342-4382 | Full-service OSHA & occupational safety training center; provides safety and compliance courses including fall protection. |

| First Choice Safety Solutions, LLC | 800 Flanders Rd, Unit 1-1, Mystic, CT 06355 | 1-844-343-3277 | Safety, rescue, access, and training provider offering fall protection and rescue training; can train onsite. |

| Industrial Safety & Rescue | 348 Turnpike Street, Canton, MA 02021 (serves all CT) | (781) 828-2049 • 1-800-244-1238 | New England–based company providing fall protection training across CT job sites. |

| HAZWOPER Center (Online Fall Protection Training for CT) | Online Training | (817) 874-5000 | Offers a 2.5–3.5 hour OSHA Fall Protection online training marketed for CT workers. |

How Much Does Fall Protection Cost?

| Training Type / Situation | Approximate Cost / Price Range* |

|---|---|

| Basic online fall protection course (short, 1 hr–few hrs) | ~$25–$50 |

| Mid-level online/basic “competent person / user” training (more comprehensive) | ~$50–$100 per person |

| In-person or virtual instructor-led training (with small group) | ~$150–$350 per person |

| More comprehensive or specialized training (inspection, rescue, advanced, multiple days) | ~$300–$800 per person |

| On-site group training (single session for many employees) | $500–$2,000+ for the session (depends on group size & scope) |

*These are ballpark figures — actual prices vary by provider, location, and scope.

For example:

- A typical “awareness-level” online course might cost under $30–$50.

- A comprehensive in-person or advanced “competent person / full fall protection” training might run $150–$350 per person, or more depending on hands-on work and certification level.

- For large groups, on-site group sessions may have pricing based on entire session (e.g. $500–$2,000+), which when divided by number of participants can bring per-person cost down if many attend.

Is Connecticut Under Federal OSHA or Its Own OSHA Program?

Good question—and one that a lot of people get wrong.

| Category | Construction (OSHA 1926) | General Industry (OSHA 1910) |

|---|---|---|

| Training Requirement Standard | 1926.503 | 1910.30 |

| When Training Is Required | Anytime workers face a fall hazard | Anytime workers use fall protection systems |

| Minimum Topics to Cover | PFAS, ladder safety, scaffold use, fall hazards, rescue plan, equipment inspection | PFAS, ladder safety systems, positioning & restraint systems, equipment use |

| Required Trainer Qualification | “Qualified person” | “Qualified person” |

| Follow-Up Training | When unsafe behavior observed, new equipment introduced, job changes | Same requirements |

Connecticut does NOT have its own separate OSHA plan for private employers.

Here’s how it works:

✔ Private-sector workers (construction, warehouses, roofing, etc.)

These fall under Federal OSHA 1910 (General Industry) and 1926 (Construction).

So if you’re a roofer in Hartford, a carpenter in Bridgeport, or a solar installer in New Haven, your fall protection rules come straight from federal OSHA.

✔ State and municipal employees

Connecticut has a limited state OSHA plan called CONN-OSHA, but it only covers:

- state workers

- municipal workers (public works, utilities, town employees)

Private employers do not fall under CONN-OSHA. They follow federal OSHA.

So for fall protection training, your rules depend on who signs your paycheck.

This covers the requirements for both, but most people reading this fall under federal OSHA.

Differences Between Federal OSHA & CONN-OSHA (State Employees)

| Item | Federal OSHA | CONN-OSHA (State & Municipal Workers) |

|---|---|---|

| Who Is Covered | Private-sector workers | State + municipal employees only |

| Fall Protection Requirements | OSHA 1910 & 1926 | CT regs mirroring OSHA |

| Inspections | Federal OSHA | CT Dept. of Labor |

| Penalties | Federal fines | State enforcement actions |

| New Hire Training | Employer must provide | Employer must provide |

OSHA Fall Protection Training: What Connecticut Workers MUST Know

Let’s get to the heart of it:

OSHA requires fall protection training for anyone exposed to a fall hazard.

Not “only roofers.”

Not “only people working on scaffolds.”

Not “only those above 6 feet.”

If there’s a fall hazard, workers must be trained.

Here’s what OSHA says in plain English:

Federal OSHA 1926.503 – Construction Training Requirements

If you’re doing construction work where falls can happen, employers must provide training that covers:

- identifying fall hazards

- proper use of guardrails, PFAS (personal fall arrest systems), lifelines, anchors

- proper ladder and scaffold use

- how to inspect equipment

- how to prevent falls through holes, skylights, edges

- rescue procedures

- when fall protection is required (heights)

Training must be site-specific, not just generic slideshows.

Federal OSHA 1910.30 – General Industry Training Requirements

General industry workers (warehouses, factories, telecom, maintenance, HVAC at facilities) must be trained on:

- fall protection systems

- personal fall arrest systems

- positioning systems

- travel restraint

- ladder safety systems

And here’s one more key thing: Training must be done by a “qualified person.”

That means someone with actual knowledge—not the intern who watched a YouTube video.

Most Common OSHA Fall Protection Violations

| Violation Type | OSHA Reference | Why It Happens |

|---|---|---|

| Missing Training Docs | 1926.503 | No certificates or rosters |

| Improper Harness Use | 1926.502(d) | Wrong adjustment or connection |

| No Anchor Points | 1926.502 | Workers tie off to unsafe objects |

| Ladder Misuse | 1926.1053 | Wrong angle, damaged ladders |

| Scaffold Guardrails Missing | 1926.451(g) | Poor setup or rushing |

| Skylights Not Guarded | 1910.28 | Believed to be “not a hole” |

The Connecticut Twist: Where CT Has Extra Rules

Even though CT doesn’t have its own full OSHA plan, there are some areas where state-level requirements kick in, especially for public works and government employees.

Here’s what’s unique to Connecticut:

A. CONN-OSHA for Public Employees

State and municipal workers must follow:

- Regulations of Connecticut State Agencies Section 31-372-5

- Public employee training requirements

These mirror federal OSHA but are enforced by the Connecticut Department of Labor.

B. CT Construction Projects Often Require Extra Documentation

On many state-funded projects (schools, road projects, utilities), they want to see:

- proof of worker training

- written fall protection plan

- scaffold and ladder training records

- competent person designation

I’ve worked on DOT and state school projects here—trust me, they check your paperwork.

C. CT Insurance Carriers Are Tough

I’ll say this from experience: Connecticut insurance auditors are stricter than most states.

Workers’ comp audits often want to see:

- fall protection training certificates

- retraining logs

- proof of daily inspections

- supervisor competency documentation

If you can’t produce it, your premiums go up.

So even though CT follows federal OSHA, the level of enforcement often feels tougher.

What Height Does OSHA Require Fall Protection In CT?

Same as the rest of the U.S., but here’s the easy breakdown:

Construction (OSHA 1926)

- 6 feet: walking/working surfaces

- 10 feet: scaffolds

- 15 feet: steel erection (special exceptions)

General Industry (OSHA 1910)

- 4 feet: walking/working surfaces

- 5 feet: stacking materials

- 6 feet: holes and unprotected edges

- No height: if you can fall into dangerous equipment

| Work Type | OSHA Standard | Fall Protection Required At |

|---|---|---|

| Construction (general) | 1926 Subpart M | 6 ft |

| Construction – scaffolds | 1926.451 | 10 ft |

| Construction – steel erection | Subpart R | 15 ft (with exceptions) |

| General Industry | 1910 Subpart D | 4 ft |

| Holes & openings | 1910.28 | Any height |

| Dangerous equipment | 1910.28 | No height requirement (always required) |

If you’re above these heights—or even close—and there’s no protection, training is REQUIRED.

The Bottom Line: Connecticut Expects You to Take Fall Protection Seriously

Here’s the truth, from someone who has spent years on CT sites:

Falls are still the #1 killer in construction.

And most of the deaths happen because people weren’t trained—or weren’t trained well enough.

Connecticut may not have its own unique fall protection laws like California, but the state enforces the federal rules aggressively. Between OSHA, CONN-OSHA for public workers, insurance carriers, GC requirements, and safety audits, training isn’t something you can slide past.

If you’re a worker:

Training keeps you alive.

If you’re an employer:

Training keeps OSHA off your back and your costs down.

If you’re a contractor bidding CT jobs: Training keeps you from being kicked off site.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

View All Articles