If you work at heights in Delaware—whether you’re roofing in Wilmington, climbing ladders in Dover, or unloading at the Port of Wilmington—you’ve probably heard the same reminder over and over:

“Make sure you’re tied off.”

And honestly? There’s a good reason for that. Falls continue to be the No. 1 killer in construction, nationwide and right here in Delaware. And it’s not always the dramatic 30-foot falls that do the damage. Sometimes it’s a simple ladder slip at 8 feet, or a misstep near an unprotected edge at 6 feet.

So today, let’s break down what fall protection training in Delaware really looks like, the OSHA rules that apply, who needs the training, and what you can expect from the class—told in a simple, conversational way from someone who’s been around enough jobsites to know what actually happens out there.

Does Delaware Have Its Own Fall Protection Rules?

Short answer: No.

Delaware follows federal OSHA. There isn’t a separate “Delaware OSHA” or state plan like California or Washington.

What does that mean for you?

It means that if you work in Delaware:

- You follow OSHA 1910 (General Industry), or

- OSHA 1926 (Construction)

Let’s keep this simple:

1. OSHA 1910 – General Industry (for warehouses, plants, manufacturing, maintenance)

Fall protection starts at 4 feet.

Yes—four.

That’s why warehouse workers, HVAC techs, maintenance staff, and manufacturing employees often get cited. They think fall protection is a “construction thing.” Nope.

2. OSHA 1926 – Construction (for roofing, framing, trades, towers)

Fall protection starts at 6 feet.

So if you’re framing a wall, installing solar panels, working on a scaffold, or roofing… the 6-foot rule is your new best friend.

Simple breakdown:

If you’re building it → 6 ft

If you’re maintaining it → 4 ft

Nothing fancy. Nothing extra. But you do have to understand which one applies to you, because the height rules are different.

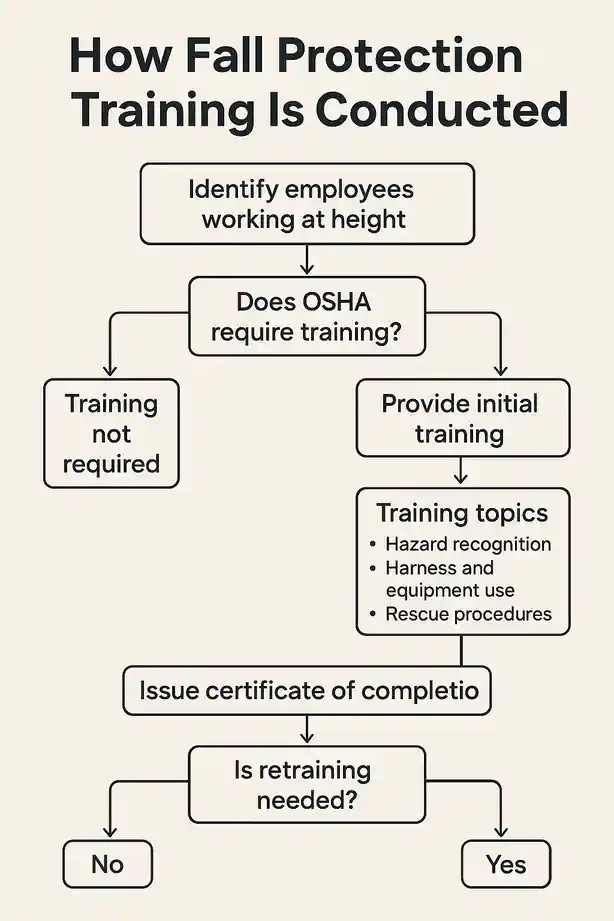

This is How the Training is Delivered

How Much Does the Training Cost?

| Training Type | Typical Cost Range | Included Topics | Who Should Take It | Certificate Duration |

|---|---|---|---|---|

| Basic Fall Protection Awareness (4–6 hours) | $75 – $200 | • Identifying fall hazards• Proper ladder use• Harness basics• How to use lanyards/SRLs• Anchor point basics• Guardrail rules• Fall clearance awareness | New workers, general construction workers, warehouse employees, maintenance staff | 1–3 years (varies by provider; refresher required when unsafe behavior is observed) |

| Competent Person Fall Protection Training | $250 – $500 | • Hazard assessment• Selecting proper fall protection systems• Inspecting fall protection equipment• Creating rescue plans• Site-specific hazard controls• Supervising work at heights | Foremen, supervisors, safety officers, anyone expected to enforce fall protection rules | 2–3 years (OSHA requires retraining when job duties change) |

| Authorized User Training (Hands-on Focused) | $150 – $300 | • Full-body harness fitting & adjustments• SRL and shock lanyard use• Calculating fall distance• Anchor selection• Hands-on practice with equipment | Workers who actually use harnesses, lanyards, SRLs, and work on lifts or roofs | 1–2 years (or sooner if work conditions change) |

| Aerial Lift Training (Boom/Scissor Lift) | $100 – $250 | • Fall protection in lifts• Tie-off requirements• Platform & guardrail rules• Safe operation practices• Rescue planning | Workers operating boom lifts or scissor lifts, painters, electricians, maintenance techs | 2–3 years (operator evaluation required when performance issues occur) |

| Scaffold User Training | $100 – $250 | • Scaffold access• Guardrail requirements• Fall risk zones• Platform safety• Weather considerations | Scaffold workers, laborers, carpenters, bricklayers | 2–3 years |

| Online Fall Protection Awareness (non-hands-on) | $20 – $60 | • Basic hazard awareness• Ladder rules• General fall protection concepts• Common jobsite risks | Workers needing refresher training, companies needing quick compliance updates (NOT sufficient for hands-on roles) | Varies; often 1 year (best used as refresher, not initial training) |

| Group Onsite Training (Company Training) | $800 – $2,000+ depending on class size | • Site-specific hazard evaluation• Full fall protection program• Hands-on fitting & inspection• Ladder, scaffold, aerial lift integration• Rescue plan development | Entire crews, construction companies, warehouses, plants, facility teams | 1–3 years, based on company policy and OSHA retraining triggers |

Fall Protection Training Providers in Delaware

| Provider | Address / Location / Service Area | Phone / Contact | Notes |

|---|---|---|---|

| Delaware Safety Council | Serves Delaware (courses offered to local students) | Not clearly listed — contact via website | Offers OSHA-standard fall protection classroom courses covering fall arrest systems, inspection, compliance. |

| Edge Fall Protection | Serves Delaware (construction & industrial sectors) | Contact through website — phone not clearly public | Provides fall protection services for Delaware, including consult + likely training or safety solutions. |

| OSHA Training Wilmington DE | Wilmington, DE area | Listed on website (for general OSHA training) — contact via website | Offers OSHA 10-hour / 30-hour, confined space & “competent person” certifications — may include fall protection training when requested. |

| Med‑Tex Services | Regional safety training provider (could serve DE) | Contact via website | Offers a wide range of OSHA safety training courses including fall protection training. |

| Malta Dynamics | Offers on-site training; may support Delaware clients depending on project location | Contact via website | Provides fall protection training (among other safety courses) targeted at crews needing OSHA compliance. |

Who Actually Needs Fall Protection Training in Delaware?

Let me tell you something: people are always surprised when they find out their job does require fall protection training.

Most say: “Fall protection? I’m not a roofer.”

But OSHA doesn’t care what your job title is—OSHA cares where your feet are standing. Or more accurately, how far they are from the ground.

Here’s who needs training in Delaware:

| Occupation / Role | Why They Need Fall Protection Training | Typical Fall Hazards They Face | Related OSHA Standard (1910 or 1926) |

|---|---|---|---|

| Roofers | Constant work at edges, slopes, and open sides | Roof edges, skylights, wind exposure | 1926 |

| Solar Panel Installers | Always working on rooftop systems at varying pitches | Steep roofs, loose panels, skylights | 1926 |

| Carpenters & Framers | Build at height before guardrails or flooring are installed | Open edges, wall plates, leading edges | 1926 |

| Ironworkers | Perform steel erection at major heights | Beams, columns, decking, connectors | 1926 Subpart R |

| Construction Laborers | Support roles often involving ladders, platforms, scaffolds | Edges, holes, debris on elevated areas | 1926 |

| Scaffold Workers | Work on temporary elevated platforms | Missing guardrails, plank failures | 1926 Subpart L |

| Telecom Tower Workers | Climb towers and poles at extreme heights | Tower climbing, antennas, high winds | 1910/1926 (depends on work) |

| HVAC Technicians | Regularly climb roofs, ladders, and service elevated units | Roof edges, ladders, slippery surfaces | 1910 (maintenance) |

| Painters (Residential & Commercial) | Work on ladders, lifts, and platforms | Ladder slips, edges, unstable surfaces | 1926/1910 |

| Electricians | Use ladders and lifts, open ceilings, rooftops | Mezzanines, overhead work, exposed edges | 1910/1926 |

| Warehouse Workers | Warehouse falls start at just 4 feet | Order-pickers, mezzanines, loading docks | 1910 |

| Maintenance Technicians | Work in mechanical rooms, roofs, elevated catwalks | Ladder use, catwalks, mezzanine edges | 1910 |

| Window Installers | Work at building exteriors using ladders & lifts | Edges, unprotected openings, ladders | 1926 |

| Glaziers | Install glass on multistory buildings | Open edges, suspended platforms | 1926 |

| Anyone Using Ladders Regularly | Ladder use itself requires training due to fall risk | Ladder collapse, overreach, misuse | 1910.23 |

| Workers on Aerial Lifts (Boom / Scissor) | Must be tied off inside the lift when required | Lift movement, platform edges | 1926.453 |

| Workers Handling Materials at Heights | Even non-construction roles require training if elevated | Edges, openings, mezzanine drops | 1910 |

| Anyone Working Around Holes, Skylights, Mezzanines | These are hidden fall hazards OSHA cites frequently | Unprotected skylights, floor openings | 1910 / 1926 |

| Warehouse Pickers & Forklift Order Operators | Elevated picking platforms require fall protection | Platform edges, sudden movement | 1910 |

| Facility & Building Service Workers | Access rooftops for inspection or repair | Edges, ladder use, slippery surfaces | 1910 |

| Construction Supervisors & Foremen | Must understand hazards crew members face | Leading edges, oversight responsibilities | 1926 |

| New Hires in Any Trade Working Off Ground Level | OSHA requires training before exposure to hazards | All above risks depending on job | 1910 / 1926 |

Final Thoughts: Staying Safe in Delaware Isn’t About Pass/Fail—It’s About Going Home

Here’s the truth:

Fall protection isn’t about passing an OSHA audit.

It’s not about certificates on the wall.

And it’s definitely not about impressing anyone.

It’s about going home in one piece.

Delaware may be small, but its jobsites are just as risky as anywhere else. And fall protection training—done right, not rushed—can literally save someone’s life.

So whether you’re a new hire climbing your first ladder or a foreman who’s been roofing since the ’90s, the rules apply to all of us. Stay trained, stay tied off, and stay alert. Your family cares more about you being safe than your boss cares about you being fast.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

View All Articles