If there’s one question I get asked over and over again when I’m out on job sites, it’s this:

“How Often Do You Need Fall Protection Training?”

And I get why people ask. Training takes time, job sites are busy, and everyone wants a clear number. But here’s the truth I’ve learned after years of doing safety inspections, correcting unsafe practices, and retraining hundreds of workers:

👉 Fall protection training isn’t a one-time event — it’s an ongoing practice.

Let me break this down the same way I explain it to supervisors and crews on site.

| Category | General Industry | Construction Industry |

|---|---|---|

| OSHA Requirement | No fixed timeline. Retraining required “as needed.” | Same rule: retraining required “as needed.” |

| Common Best Practice | Refresher every 1–2 years | Refresher every year or more often |

| Hands-On Retraining | Every 2 years or when new equipment is introduced | Every year due to higher hazard levels |

| When Jobsite Changes | Happens less often → retraining not required as frequently | Happens frequently → retraining needed more often |

| After Near Miss or Incident | Required immediately | Required immediately |

| When New Fall Protection Gear Is Introduced | Required when new systems or equipment are used | Required when new equipment, scaffolding, or site setup changes |

| Worker Skill Fade | Usually slower — tasks are more repetitive | Faster — tasks and hazards change daily |

| Hazard Level | Moderate (platforms, ladders, mezzanines) | Higher (roofing, edges, scaffolding, leading edges) |

| Typical Real-World Frequency | Once a year for refreshers | Every 6–12 months depending on risk |

| Who Usually Oversees Training | Safety manager or EHS specialist | Competent person, site supervisor, or external trainer |

| Work / Exposure Level / Context | Recommended Training Frequency | Notes / Conditions |

|---|---|---|

| General industry (non-construction, lower fall-risk workplaces) | Every 1–2 years | Retraining ensures recall and compliance even if not strictly required by rule. |

| Construction work (or medium-risk worksites) | Every 1 year | Frequent hazards and changing site conditions justify a tighter refresher schedule. |

| High-hazard worksites (e.g. roofing, telecom, tower climbing, oil & gas, dynamic environments) | Every 6–12 months | Because of changing conditions: equipment, anchors, personnel — more frequent refreshers are ideal. |

| New assignment / New hazard exposure / New equipment / New rescue procedures | “Before exposure” — i.e. immediately, at onboarding or when conditions change. | Regardless of prior training history — training must precede first exposure to fall hazard or use of protection equipment. |

Read Related Article: Who Can Give Fall Protection Training? (And Who Cannot)

What OSHA Actually Requires (The Real Answer Most People Don’t Know)

A lot of folks think OSHA requires training every year.

Some think it’s every 2 years.

Others say every 3.

But OSHA is surprisingly flexible about it. Instead of giving a fixed time, OSHA says workers must be trained and retrained whenever necessary.

This means you need retraining when:

- The worker doesn’t remember how to use the equipment

- Their behavior shows they misunderstood the rules

- The job introduces new hazards or different equipment

- A worker is involved in a near miss or fall incident

- Regulations change

- The previous training is no longer adequate

In other words, OSHA cares less about the calendar — and more about whether your workers are actually competent.

Read This Article: Does OSHA Require Fall Protection Training Annually?

When OSHA Requires Retraining

| Retraining Trigger | Description | Why OSHA Requires It |

|---|---|---|

| Unsafe behavior observed | Worker misuses harness, anchor, or procedures | Shows lack of understanding or skill |

| Near-miss or incident | Any fall-related close call | Indicates training gaps |

| Changes in workplace hazards | New heights, new tasks, new environment | Old training no longer applies |

| New fall protection equipment introduced | New harnesses, SRLs, anchors, systems | Workers must learn new equipment |

| Worker is assigned a new job role | Switching from warehouse to construction, etc. | Different fall hazards |

| Employer believes worker needs it | Performance issues, confusion, bad habits | OSHA leaves final judgment to the employer |

What I’ve Seen on Real Job Sites

Let me share something from experience.

When I inspect harnesses or watch a crew working at heights, I can usually tell within 30 seconds who needs retraining. Simple signs like:

- Chest strap riding up into the neck

- Loose leg straps

- Lanyards anchored at foot level

- No inspection being done

- SRLs being pulled incorrectly

- Workers unsure how to calculate fall clearance

And you know what?

These issues don’t happen because workers don’t care. They happen because it’s been too long since the last training.

I’ve retrained crews who had “training cards” from 3 months ago — but they still missed basics. And I’ve met workers trained 2 years ago who are still solid because their supervisors enforce good habits daily.

Read More About This Topic: Fall Protection: Whose Responsibility Is It—Employer or Worker?

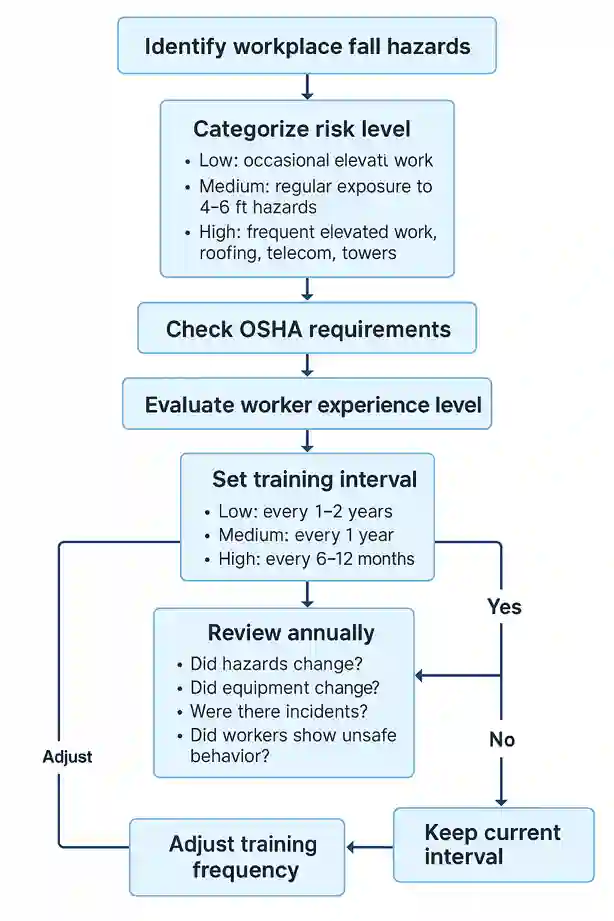

How Employers Decide Fall Protection Training Frequency

So… How Often Do You Need Fall Protection Training?

Based on OSHA guidance and what I’ve personally seen keep workers safe, this is the schedule I always recommend:

Annual Refresher Training (Once a Year)

This is the sweet spot.

A yearly refresher covers:

- Equipment inspection

- Proper harness fitting

- Anchor point selection

- SRL vs. lanyard choices

- Rescue plans

- Real-world scenarios from your job site

Most companies stick to this, and it works well.

Full Retraining Every 2 Years

A deeper session with hands-on practice, updated equipment, and new safety regulations.

3. Immediate Retraining When:

- A near miss happens

- You introduce new fall protection systems

- A worker transfers to a different role (e.g., ground worker to elevated platform)

- Someone shows unsafe habits

Trust me — if your gut tells you a worker needs retraining, you’re right.

High-Risk Environments = More Frequent Training

If you’re in roofing, telecom, tower climbing, oil & gas, or any high-exposure job, training every 6–12 months is ideal.

These job sites change fast, and so do the hazards.

Read More About This Topic: Qualified vs. Competent Person in Fall Protection

Why Frequent Training Actually Saves Time (And Money)

One thing I always remind employers is this:

Training is cheaper than an accident.

A harness costs $150.

A rescue can cost thousands.

A fall-related injury? It can cost a company six figures.

Not to mention, a fall can change someone’s entire life in seconds.

When workers know exactly how to protect themselves, they:

- Work confidently

- Avoid mistakes

- Help keep co-workers accountable

- Reduce downtime

- Improve jobsite efficiency

The return on good training is huge.

Key Takeaway

How Often Should Fall Protection Training Be Done?

If you’re in general industry, a solid schedule is:

👉 Refresher every 1–2 years

👉 Retrain sooner if equipment or hazards change

If you’re in construction, training needs to be more frequent because the jobsite changes constantly:

👉 Refresher every 6–12 months

👉 Retrain anytime the site setup, gear, or tasks change

Construction environments are dynamic, so keeping crews updated is critical for preventing falls.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

View All Articles