If you’re looking for the right way to store fall protection equipment, you’re already on the right track.

Most workers focus on using the gear, but forget that storage is what actually destroys harnesses, lanyards, SRLs, and anchors long before a fall ever happens.

I’ve seen enough jobsites to know: fall protection usually fails because it was stored wrong—not because it was used too much.

I’ve watched harnesses bake in hot trucks, lanyards tossed into muddy buckets, and SRLs crushed under toolboxes. People assume gear fails because it’s “old,” but honestly? Most of the time it’s because someone treated it like an old pair of gloves.

So let’s keep it simple. Just real, experience-based advice on how to store your fall protection gear so it stays strong and ready when you need it.

Recommended Storage Locations for Fall Protection Equipment

| Storage Location | Why This Location Is Ideal | Pros | Cons |

|---|---|---|---|

| PPE Cabinet | Designed specifically for storing safety gear. Usually kept indoors in a controlled environment—dry, clean, and away from sunlight and chemicals. Provides a dedicated space so PPE doesn’t get mixed with tools or equipment. | – Protects gear from moisture, heat, and UV exposure- Organized and easy to inspect- Keeps gear away from contaminants- Lockable for security | – Requires indoor space- Not always available on smaller jobsites |

| Gear Bag (Mesh/Canvas) | Breathable material prevents moisture buildup and mold. Easy to carry, ideal for workers who move between sites. Keeps all equipment together and protected from dirt and sharp objects. | – Portable and convenient- Prevents gear from getting crushed- Mesh allows airflow to keep gear dry- Keeps components organized | – Can still trap moisture if gear is stored wet- Needs to be kept in a clean, dry place- Not ideal as a sole long-term storage solution |

| Work Truck Storage Box | Good for workers who travel between sites. Provides a secure, enclosed space for gear. When used correctly, it protects PPE from external damage and contamination. | – Convenient for mobile workers- Keeps gear separate from loose tools- Protects against weather if sealed properly | – Can get very hot inside (damages webbing)- Can build condensation- Needs dividers or bags to prevent crushing |

| Personal Locker | Ideal for individual control of gear. Offers a dry, enclosed, and personal space away from chemicals and tools. Workers are more likely to store gear properly when they have a dedicated locker. | – Encourages personal accountability- Protects from theft or accidental misuse- Safe from sunlight and weather- Consistent environment | – Limited airflow (must dry gear before storing)- May be cramped without hooks or shelves |

| Tool Room Area (Clean Section) | Centralized, controlled space for PPE if cabinets or lockers aren’t available. Works well when there’s a designated PPE corner or rack separate from tools, chemicals, and welding equipment. | – Good for shared access- Easy for supervisors to check and organize- Usually indoors and climate stable- Allows for proper hanging and separation of gear | – If not separated from tools, gear may get contaminated- Requires discipline to maintain cleanliness- Not secure if multiple people access the area |

How Each Fall Protection Component Should Be Stored

When it comes to storing fall protection gear, every piece has its own preferences. Your harness doesn’t want the same treatment as your SRL, and your lanyard definitely isn’t meant to be bent, twisted, or stuffed into a bag like an old extension cord.

Each component has its own “happy place” when it comes to storage, and if you treat them right, they’ll last longer and keep you safer. So let’s break down, in simple terms, how to store each part so your whole setup stays in good shape.

| Equipment Type | Correct Storage Method | Common Mistakes to Avoid |

|---|---|---|

| Harness | Hang by D-ring; keep dry | Folding, stuffing in bags |

| Lanyard | Coil loosely | Knotting, crushing shock pack |

| SRL | Store upright, line retracted | Storing on side, moisture |

| Anchor straps | Hang or coil | Storing wet, near sharp tools |

| Connectors | Keep clean & dry | Rust, chemical exposure |

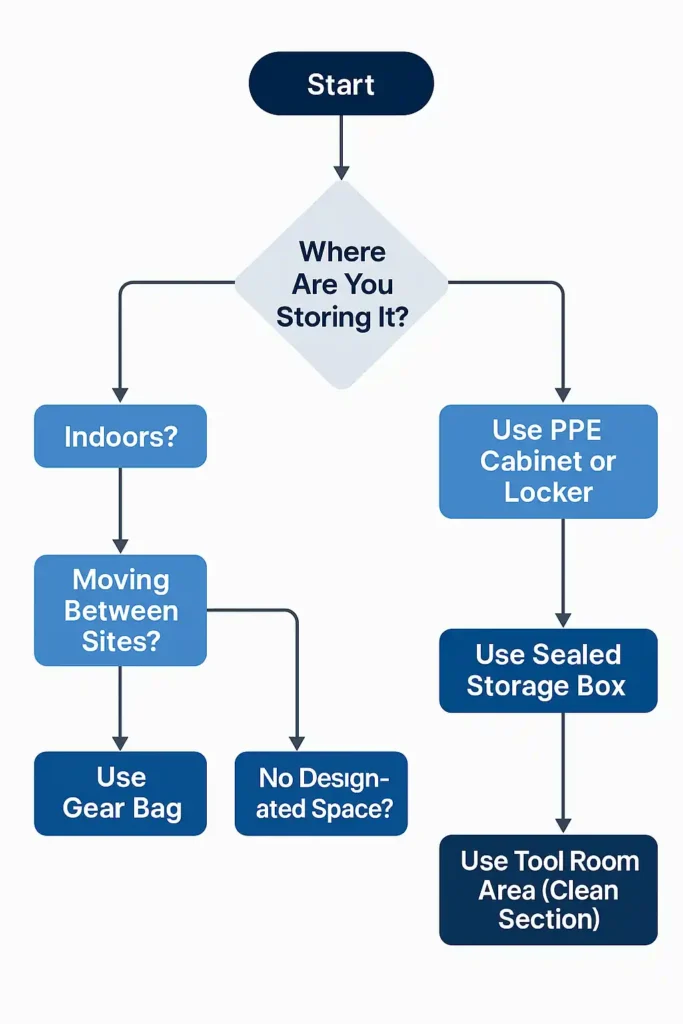

Choosing the Right Storage Location

Daily Storage Routine Checklist

A simple step-by-step checklist formatted into a table:

- Shake off debris

- Ensure dryness

- Check hardware

- Coil/hang properly

- Separate from tools

- Store in ventilated bag

- Report damaged gear

“Never Do This” List

| DO | DON’T |

|---|---|

| Keep gear dry | Leave wet in gang box |

| Store away from sunlight | Dry on dashboard |

| Use ventilated gear bag | Store in plastic bag |

| Protect hardware | Toss with metal tools |

| Keep separate from chemicals | Store near paint or fuel |

Gear Lifespan With Proper vs Poor Storage

Fall protection gear has a pretty simple rule: take care of it, and it’ll take care of you. But ignore it—leave it wet, bake it in your truck, toss it under tools—and it’ll fall apart way sooner than you’d expect.

I’ve seen gear last nearly a decade, and I’ve seen brand-new harnesses ruined in a few months, all because of how they were stored. Here’s a quick look at how long your equipment can really last when you store it the right way… versus what happens when you don’t.

| Equipment | Proper Storage Lifespan | Poor Storage Lifespan |

|---|---|---|

| Harness | 5–10 years | 6 months–2 years |

| Lanyards | Multi-year | Less than 1 year |

| SRLs | 5+ years | 1–2 years |

| Anchor straps | Long-lasting | Rapid fraying/damage |

Why Storage Matters More Than People Think

Let me start with this: fall protection gear is life support equipment. You’re literally depending on it to stop you from becoming a jobsite statistic. Yet it’s the same gear that gets tossed around the most.

I’ve seen guys treat their harness well while they’re wearing it, then the moment they unclip, they throw it like it’s laundry. But here’s what most people don’t realize:

- Heat breaks down webbing.

- Moisture breeds mold.

- Chemicals can weaken straps without you ever noticing.

- UV light slowly cooks your harness.

- Dirt, metal shavings, and tools can damage stitching and fibers.

And when one small part of your gear fails, the whole system fails.

Good storage isn’t just about “being organized.” It’s about keeping the gear safe so it can keep you safe.

The Golden Rule: Treat Your Gear Like It’s Going to Save Your Life

Because it will. Not “might,” not “maybe”—it will.

People sometimes laugh when they see me carefully hanging my harness up or storing my SRL upright, but I don’t do it for aesthetics. I do it because I’ve seen what happens when someone doesn’t.

You’d be shocked how many “accidents” were actually gear that was ruined long before it was even used.

If you take one thing from this whole article, let it be this:

Store your gear like you’ll need it to save your life tomorrow.

Final Thoughts: Respect the Gear, and It’ll Respect You

At the end of the day, fall protection gear isn’t hard to take care of. It just needs a little respect. The better you store it, the longer it lasts—and the safer you are when you clip in.

You only get one body and one life. Treat the gear that protects it like something valuable. Because it is.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

View All Articles