If you’re trying to choose a fall protection training provider, let me tell you something from experience: not all training is created equal.

Some classes will actually teach you how to stay alive on a roof, beam, or lift… and some will just hand you a certificate and hope you don’t ask questions.

I’ve taken and delivered enough fall protection classes to see the difference between good training, bad training, and “please don’t let OSHA walk in” training.

So in this guide, I’ll break down—casually and straight from the field—how to pick the right provider without wasting your time or putting your workers at risk.

Let’s get into it.

| Trade / Occupation | Key Hazards For This Trade | What to Look For in a Training Provider | Why This Matters |

|---|---|---|---|

| Roofers | Roof edges, skylights, unstable surfaces | Provider must cover roofing-specific fall arrest, warning-line systems, anchor point selection | Roofing hazards are unique; wrong method = fatal falls |

| Carpenters & Framers | Floor openings, ladders, framing edges | Provider that teaches harness use, guardrails, ladder safety, hole/shaft protection | Carpenters encounter changing structures daily |

| Solar Installers | Roof slopes, panel installation angles | Provider with rooftop solar-specific training, positioning systems | Solar installs require precise positioning & anchoring |

| Electricians | Ladders, mezzanines, aerial lifts | Training must include ladder safety + MEWP training + arc-flash considerations | Electricians combine height + electrical hazards |

| HVAC Technicians | Rooftops, attic spaces, ductwork | Provider with rooftop PPE use, platform access, and constrained-space anchoring | Rooftop units often require unusual tie-off points |

| Ironworkers / Steel Erectors | Structural steel, open edges, beams | Provider specializing in leading-edge & steel-erection fall protection | Steel erection falls are among highest fatality rates |

| Painters | Ladders, lifts, scaffolds | Training must include ladder use, scaffold safety, lift operation | Painters frequently switch between elevations |

| Window Installers | Exterior edges, ladders, swing stages | Provider must teach anchor selection and suspended platforms | One of the highest-risk finishing trades |

| Warehouse Workers | Mezzanines, order pickers, docks | Provider that covers order picker PPE + general industry fall rules | Warehouses face the OSHA 4-ft rule + equipment hazards |

| Telecom Tower Workers | Towers, climbing systems | Provider must offer tower climbing & radio frequency safety certification | Tower climbing requires specialized, regulated training |

| Maintenance Technicians | Ladders, mezzanines, platforms | Provider should include mixed-environment fall hazards: ladders + platforms + equipment | Everyday tasks involve unpredictable hazards |

| Truck Drivers | Trailer tops, loading, docks | Provider teaching fall protection for trailers + dock fall hazards | Many trucking-related falls are from trailer tops |

| Scaffold Workers | Erecting/dismantling scaffolds | Provider must cover scaffold fall arrest, drop hazards, and scaffold-specific tie-off points | Scaffold erection is uniquely dangerous |

| Wind Turbine Technicians | Ladders, tower climbing | Must use a GWO-compliant or tower-specific provider | Wind techs need advanced rescue & ladder systems |

| Hospital Maintenance Staff | Rooftops, ladders, equipment rooms | Provider must cover rooftop edges + confined walkways | Hospitals have hidden fall risks in mechanical rooms |

| Tree Trimmers / Arborists | Trees, aerial lifts | Provider must include lift safety + rope/carabiner systems | Arborists face vertical and swing fall hazards |

First: Understand What YOU Actually Do at Work

Before you even look at a provider, stop and think:

What hazards do you or your guys face daily?

Because trust me—roofers, warehouse workers, electricians, solar installers, ironworkers, and maintenance techs do not need the exact same kind of fall protection training.

Roofing work? That’s leading-edge and rooftop anchor points.

Warehouse work? That’s order picker PPE and the OSHA 4-ft rule.

Ironwork? Completely different game—steel beams, risers, connectors, and exposed edges.

A good training provider understands those differences. A great one teaches a class that fits your actual job, not just generic “don’t fall” PowerPoint slides.

If the provider doesn’t know your trade?

Skip them. They’re not the one.

Make Sure the Provider Covers OSHA Standards

Here’s something the cheap providers don’t tell you: OSHA does require fall protection training, but OSHA never tells you who can train you. That means you’ll find random “trainers” who have never touched a harness in their life.

At a minimum, your training must match:

- OSHA 1926 Subpart M (construction)

- OSHA 1910.28 (general industry fall protection)

- OSHA 1910.30 (training requirements)

If a provider can’t tell you which standards they follow?

If they say “Oh yes, we meet OSHA standards” but can’t give details?

Huge red flag.

You want someone who says:

“We train under 1926 Subpart M, 1910.28, 1910.30—and here are the topics we include.”

That’s how you know they actually know what they’re doing.

Hands-On Training Is Non-Negotiable

Look, I love a good slideshow as much as the next guy, but fall protection isn’t something you learn by staring at pictures. You need hands-on time with real gear.

A solid provider will let you:

✔ Inspect harnesses

✔ Practice putting them on correctly

✔ Adjust leg straps and chest straps

✔ Test your lanyard or SRL

✔ Choose a proper anchor point

✔ Practice making safe connections

✔ Learn real rescue basics

If a provider says:

“Everything can be done online.”

Or…

“The hands-on part is optional.”

Walk away. That’s not OSHA-compliant.

Hands-on work is where you learn the real stuff—how to spot a frayed webbing, how to recognize a damaged SRL, and how to tell if an anchor point is actually safe.

I’ve seen too many workers who wear their harness like a backpack because no one taught them otherwise. That’s how accidents happen.

Look for Trade-Specific Training (Not One-Size-Fits-All)

The best providers don’t shove everyone into one class. (See above table)

Instead, they tailor the training based on:

- Roofing

- Electrical / HVAC

- Warehouse

- Telecom towers

- Solar installation

- Ironwork

- Scaffold work

- Maintenance crews

- Construction laborers

When the training actually fits the job, workers stay awake, pay attention, and most importantly—they remember the information.

I’ve seen rooftop workers sit through a warehouse-focused training and leave more confused than they arrived.

Pick a provider that knows your hazards, your equipment, and your job.

Check the Instructor’s Qualifications

This one separates the pros from the pretenders.

A good instructor will have:

- OSHA Authorized Trainer credentials (Construction or General Industry)

- Field experience — actual jobsite work

- Certifications (COSS, CHST, CSP, or equivalent)

- Experience teaching real workers in your trade

- Knowledge of both PPE and hazard assessment

It’s okay to ask straight up:

“What experience do you have in fall protection and training workers in our industry?”

If they can’t answer with confidence, move on.

There are instructors who only read word-for-word from a slide deck. And then there are instructors who can actually show you how to spot a fake anchor point or how to do a harness buddy-check.

You want the second kind.

Training Should Include Equipment Inspection

This is the part people skip—and the part that causes the most problems on jobsites.

A proper fall protection class teaches you:

- How to inspect a harness

- Stitching defects to look for

- Webbing cuts, heat damage, and chemical exposure

- What makes a lanyard unsafe

- How to check an SRL for proper locking

- What “remove from service” actually means

- How to pick a real anchor point vs. a “that looks strong enough” anchor

Most fall protection failures start with bad equipment inspection.

A provider who skips this is teaching a half-class.

Rescue Training Must Be Part of the Course

Here’s the truth nobody says out loud:

Fall protection isn’t just about preventing falls—it’s also about what happens AFTER someone falls.

Suspension trauma sets in fast.

Workers panic. Your whole crew freezes because no one knows what to do.

A real training provider will teach:

✔ What suspension trauma is

✔ How to respond quickly

✔ Self-rescue techniques

✔ Assisted rescue methods

✔ How to use rescue straps

✔ What NOT to do during a rescue

If the provider doesn’t even mention rescue?

That training is incomplete.

Ask About Class Format: Classroom, Online, or Blended

Here’s the honest breakdown:

Classroom:

- Great for detailed topics

- Best for Q&A

- Good for new workers

Online:

- Good for annual refreshers

- Convenient but NOT enough for first-time workers

Blended (Online + Hands-On):

- The best option for many crews

- Covers theory online

- Actual practice done in-person

If a provider offers only online and claims it’s OSHA-approved for everything, be cautious.

OSHA requires hands-on skill demonstration for fall protection.

Course Length Matters (Short Courses = Low Quality)

If someone offers a full fall protection course in 20–30 minutes?

Close the browser.

A solid course usually includes:

2–4 hours:

- Perfect for most workers

- Covers essentials + hands-on

4–8 hours:

- Advanced courses

- Includes rescue, complex hazards, and multiple PPE types

A quality provider knows you can’t learn life-saving skills in under an hour.

The Provider Should Give Proper Documentation

You should receive a training certificate AND a record of training that includes:

- Your name

- Instructor’s name

- Training date

- Course outline / topics

- OSHA standards covered

- Expiration or recommended renewal

- Equipment used during hands-on

These documents protect you during:

- OSHA audits

- Insurance claims

- Company safety inspections

If the provider sends a generic certificate with no details, that’s a red flag.

Ask About Recertification (Some Jobs Require It Yearly)

OSHA says retraining must happen when:

- The worker shows unsafe behavior

- Equipment changes

- Hazards change

- Procedures change

Many employers schedule refreshers every year or every two years.

A good provider will explain when retraining is required and offer discounted refresher courses.

Compare Prices — But Don’t Go for the Cheapest Option

Let me tell you something I’ve learned the hard way: Training is one of the worst things to go cheap on.

What affects the price?

- Hands-on practice (this costs more but is worth it)

- Onsite vs. public classes

- Trainer experience

- Specialized trade modules

- Rescue training included or not

- Class duration

Cheap training usually means:

- No hands-on

- No equipment inspection

- Generic slides

- Fast “certificates”

- No rescue training

You get what you pay for—especially in safety.

Red Flags That a Training Provider Is No Good

Be careful if you see any of these:

🚩 Instant certificate (no test, no practice)

🚩 Instructor with no field experience

🚩 No mention of OSHA standards

🚩 Only PowerPoint, no hands-on

🚩 No documentation of skills

🚩 Certificate delivered in minutes

🚩 Course finished in under 1 hour

🚩 No rescue component

🚩 Very cheap price

🚩 No clear contact info

If any of these show up, run.

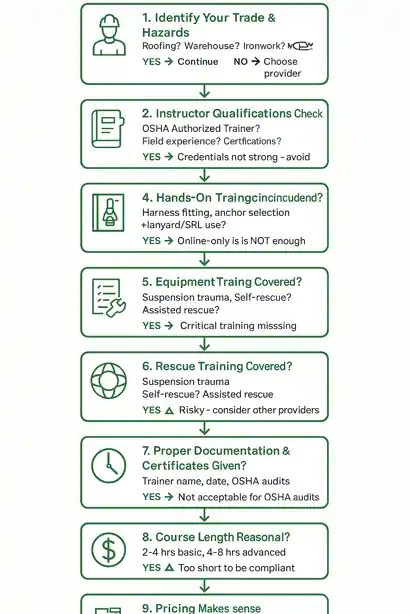

Quick Checklist Before You Choose a Provider

Before you pay, ask yourself:

✔ Does the provider understand my trade?

✔ Do they cover OSHA 1910 & 1926?

✔ Is there hands-on training?

✔ Will I learn proper equipment inspection?

✔ Does the class include rescue?

✔ Do the instructors have real experience?

✔ Do they give proper certificates and records?

✔ Is the course long enough to learn something real?

✔ Do they offer recertification?

If you can answer “yes” to most or all of these, you’ve found a solid provider.

Final Thoughts: Choose Training That Will Actually Keep You Alive

At the end of the day, choosing a fall protection training provider isn’t about getting a fancy certificate for your wallet or a piece of paper to stick in your safety file.

It’s about learning skills that could save your life on a bad day.

A good provider gives you:

- Confidence on the job

- Skills you can actually use

- A real understanding of hazards

- Knowledge that stays with you

- A safer crew and jobsite

So don’t just pick the cheapest or fastest option.

Pick the one that actually teaches you how to go home safely after every shift.

Because fall protection training is more than compliance—it’s survival.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

View All Articles