Let me tell you something upfront: choosing between in-person and on-site fall protection training sounds like a small decision… until you’re the one responsible for making sure an entire crew stays OSHA-compliant and doesn’t end up one slip away from a workers’ comp nightmare.

I’ve taken both types of training. I’ve taught both. I’ve seen companies waste money on the wrong one, and I’ve seen other companies save thousands because they chose the format that matched the way their people actually work.

So in this guide, I’m breaking down everything in plain, real-world language—not corporate safety brochure talk.

If you’re trying to figure out which training format works for YOU (or your crew, or your company), this will save you a ton of guesswork.

Comparing In-Person vs On-Site Fall Protection Training

| Factor | In-Person Training (at Training Center) | On-Site Training (at Your Job Site) |

|---|---|---|

| Training environment | Controlled classroom + demo area, designed for learning | Real work environment with actual equipment and layout |

| Hazards covered | General fall hazards, common scenarios | Site-specific hazards: your roofs, platforms, mezzanines, ladders, equipment |

| Hands-on practice | Strong hands-on with training towers, mock roofs, lifelines, demo rigs | Hands-on with your own gear, anchors, lifts, structures |

| Realism | Simulated but clean and structured | Very realistic – workers see exactly how to work safer where they actually work |

| Distraction level | Low – no production pressure, fewer interruptions | Medium to high – radios, noise, supervisors, ongoing work can interrupt |

| Trainer focus | Focused purely on teaching; no need to adapt to site conditions | Trainer splits time between teaching and analyzing your site/hazards |

| Travel needed | Yes – crew must travel to center | None – trainer comes to you |

| Impact on productivity | More downtime due to travel and full-day off-site sessions | Less downtime – easier to schedule around shifts or slow periods |

| Cost impact | Higher when you factor in tuition + travel + lost hours | Often cheaper overall for larger crews (no travel, minimal lost hours) |

| OSHA acceptance | Fully acceptable if content + hands-on meets OSHA 1910/1926 requirements | Fully acceptable and often preferred for hazard-specific training |

| Site-specific content | Limited – examples are more generic, based on “typical” jobs | High – training is tailored to your tasks, equipment, and problem areas |

| Consistency of delivery | Very consistent – structured course, same flow every time | Varies more; customized to your site and crew needs |

| Equipment availability | Training center provides full set of demo gear | Depends on what you have on-site and what the trainer brings |

| Best for | New workers, companies needing clean foundational training, multiple sites/crews | Experienced crews, unique jobsites, companies wanting site audit + training in one go |

| Bonus benefit | Workers see “ideal world” examples and best practices | Trainer can spot bad practices and unsafe anchors directly on your site |

Pros & Cons: In-Person vs. On-Site

| Training Format | Pros | Cons |

|---|---|---|

| In-Person Training | – Controlled environment, fewer distractions- Consistent training quality- Full demo equipment available- Ideal for new workers- Strong hands-on setups (towers, mock roofs, SRLs)- No need to prepare your worksite | – Travel required- Higher overall cost (tuition + downtime)- Not job-site specific- Classroom style may bore some workers |

| On-Site Training | – Real-world training in the actual work environment- No travel needed- Trainer can inspect your site for hazards- Tailored to your equipment and job tasks- Better buy-in from workers- More practical, scenario-based learning | – More distractions from jobsite activity- Requires site cleanup/preparation- Limited demo gear compared to training centers- Quality depends on the provider |

Training Duration & Format Breakdown

| Training Topic | In-Person Duration | On-Site Duration | Notes |

|---|---|---|---|

| Classroom Theory | 1–2 hours | 45–90 minutes | On-site theory is often shortened because workers want to get straight to hands-on practice. |

| Hands-On Practice | 2–3 hours | 2–3 hours | Both formats include hands-on; in-person uses mock setups, on-site uses real job equipment. |

| Equipment Inspection | 30–45 minutes | 45–60 minutes | On-site usually takes longer because you inspect actual harnesses, SRLs, lanyards. |

| Site Walkthrough | Not applicable | 30–60 minutes | Unique to on-site. Trainer identifies hazards directly on the job site. |

| Anchor Point Selection | Simulated demo: 20–30 minutes | Job-specific: 30–45 minutes | On-site allows real-world tie-off analysis. |

| Lifeline/SRL Demonstration | Full demo rigs available: 30–45 minutes | 20–30 minutes (depends on equipment) | Training centers usually have better demo gear. |

| Rescue Planning | 30 minutes (general scenarios) | 30–45 minutes (site-specific) | On-site rescue planning is tailored to your actual site layout. |

| Final Assessment / Evaluation | 15–20 minutes | 15–20 minutes | Similar duration for both formats. |

| Total Estimated Duration | 5–7 hours | 4.5–6.5 hours | On-site is often slightly faster due to less theory and no travel downtime. |

Equipment in Each Training Format

| Equipment / Training Setup | Available In-Person | Available On-Site | Notes |

|---|---|---|---|

| Training Towers | ✔ Yes — full-height towers for demonstrations | ✖ Rare — most job sites don’t have built training towers | Used for practicing climbing, tie-offs, and fall arrest demos. |

| Roof Mockups (low-slope & steep) | ✔ Yes — realistic roof simulators | ✖ Usually not available | In-person facilities often have multiple roof types set up. |

| Horizontal Lifelines | ✔ Yes — full demo systems installed | ✔ Sometimes — depends on the job site | On-site lifelines may be limited or already in use. |

| Vertical Lifelines | ✔ Yes — often part of tower setups | ✔ Sometimes — depending on existing site gear | On-site availability depends on installed systems. |

| SRL (Self-Retracting Lifeline) demo rigs | ✔ Yes — drop-test rigs + SRL demo stations | ✖ Limited — typically only the crew’s actual SRLs | Training centers allow live demonstrations of SRL lock-up and fall distance. |

| Rescue Devices (tripods, winches) | ✔ Yes — full rescue practice setups | ✔ Sometimes — depends on the employer’s equipment | Training centers can provide realistic rescue practice. |

| Drop-Test Demonstration Rigs | ✔ Yes — controlled free-fall demo equipment | ✖ Rare | One of the most powerful teaching tools, usually only found in training centers. |

| Anchors / Anchor Point Systems | ✔ Yes — multiple anchor types available for demo | ✔ Yes — workers use their actual anchors | On-site anchors provide real-world experience; training center anchors teach theory. |

| Scaffolding Setups | ✔ Often — complete scaffold training modules | ✔ If your site uses scaffolding | In-person facilities have perfect-condition scaffolds; on-site scaffolds show real issues. |

| Ladders (all types) | ✔ Yes — all ladder types available | ✔ Yes — workers’ own ladders | On-site ladders may be worn or damaged, giving better learning context. |

| Aerial Lifts (boom, scissor) | ✔ Often — for PFAS tie-off demos | ✔ If available on-site | In-person lifts are for training only; on-site lifts match real job tasks. |

| Harnesses, Lanyards, Connectors | ✔ Yes — multiple models for demonstration | ✔ Yes — workers use their own equipment | On-site training exposes misuse or damaged gear. |

| Skylight Hazard Simulator | ✔ Sometimes — skylight mockups | ✔ If your site has skylights | On-site skylight training is more accurate for roof workers. |

| Guardrail Systems | ✔ Yes — demo guardrails set up | ✔ If installed on-site | Training centers show correct setups; on-site shows real installations. |

| Confined Space Rescue Gear (if needed) | ✔ Sometimes — depends on center | ✔ If your site has confined spaces | Relevant if your fall protection overlaps with rescue needs. |

Documentation Requirements: In-Person vs. On-Site Training

| Required Document | In-Person Training | On-Site Training | Notes |

|---|---|---|---|

| Training Certificate | ✔ Provided by training center | ✔ Provided by instructor | Must include trainee name, trainer signature, and date. |

| Attendance Sheet / Roster | ✔ Always included | ✔ Must be created on-site | OSHA requires employer to prove who attended. |

| Skills Assessment / Competency Test | ✔ Written + hands-on tests included | ✔ Hands-on evaluation on actual equipment | Must verify workers can inspect, tie off, and use PPE correctly. |

| Topics Covered Checklist | ✔ Standard list from the training center | ✔ Customized to your site + hazards | Needed to show OSHA all required topics were covered. |

| Equipment Demonstration Checklist | ✔ Using demo harnesses, SRLs, anchors | ✔ Using crew’s actual equipment | Proves hands-on training was performed. |

| Site-Specific Hazard Checklist | ✖ Not included (only general examples) | ✔ Required — tailored to actual jobsite | OSHA loves on-site hazard documentation. |

| Rescue Procedures Documentation | ✔ General rescue training included | ✔ Site-specific rescue planning | Rescue plan must be documented for compliance. |

| Retraining/Refresher Records | ✔ Provided if done at center | ✔ Provided if done on-site | Employers must track retraining triggered by unsafe acts. |

| Equipment Inspection Records (Optional) | ✔ Demo only | ✔ Real inspection notes from your site | Not required by OSHA, but highly recommended. |

| Trainer Credentials | ✔ Provided by the training provider | ✔ Must be documented by employer | OSHA requires trainers to be competent/qualified. |

| Employer Verification (sign-off) | ✔ Sometimes included | ✔ Always required | Employer must verify the worker is competent for the actual job. |

What OSHA Actually Requires (and What People Get Wrong)

| OSHA Requirement | Applies to In-Person Training | Applies to On-Site Training | Notes |

|---|---|---|---|

| Qualified/Competent Trainer | ✔ Yes | ✔ Yes | OSHA requires a qualified or competent person to conduct training in both formats. |

| Hands-On Practice | ✔ Yes (mock setups, demo gear) | ✔ Yes (real equipment) | OSHA states workers must practice proper tie-off, inspection, and equipment use. |

| Site-Specific Hazard Training | ✔ Can cover basics | ✔ Required & more accurate | OSHA expects employers to train workers on hazards they actually face on their site. |

| Understanding Fall Hazards | ✔ Yes | ✔ Yes | Both formats must teach hazard recognition under 1926.503 & 1910.30. |

| Proper Use of Fall Protection Systems | ✔ Yes | ✔ Yes | Includes PFAS, harnesses, lanyards, SRLs, guardrails, etc. |

| Equipment Inspection Training | ✔ Yes (general training) | ✔ Yes (site-specific inspections) | On-site allows inspection of actual harnesses and SRLs employees use daily. |

| Written Training Documentation | ✔ Yes | ✔ Yes | OSHA requires employer to keep records of training dates, trainer, and trainee identity. |

| Retraining When Unsafe Behavior Is Observed | ✔ Yes | ✔ Yes | If a worker misuses equipment or violates safe practices, retraining is mandatory. |

| Rescue Training (What to Do After a Fall) | ✔ Yes (general scenarios) | ✔ Yes (site-specific rescue plan) | OSHA expects employers to have a rescue plan and ensure workers understand it. |

| Evaluation of Worker Competency | ✔ Yes | ✔ Yes | Trainer must verify workers can apply skills correctly. |

| Refresher Training | ✔ Required when conditions change | ✔ Required when conditions change | OSHA does not mandate annual refresher, but requires retraining if new hazards appear. |

| Communication of Job-Specific Procedures | ✔ Limited to examples | ✔ High — tailored to your site | On-site training excels here because the trainer can point out real hazards in real time. |

Before comparing the two formats, let’s clear up the big misunderstanding:

👉 OSHA does NOT care where you take the training.

👉 OSHA only cares that it’s done correctly.

Under OSHA 29 CFR 1926.503 (construction) and 1910.30 (general industry), employers must ensure workers get trained by a competent or qualified person on:

- Identifying fall hazards

- Using fall protection systems

- Correct lifeline/anchor usage

- Equipment inspection

- Proper hook-up, anchoring, and tie-off techniques

- Rescue procedures

OSHA doesn’t say “must be in-person” or “must be on-site” — they only say it has to be effective, hands-on, and site-specific enough that workers actually know how to protect themselves on their job.

So really, the question isn’t which format OSHA prefers…

It’s which format helps your workers understand fall protection better?

Now let’s get into the real comparison.

How OSHA Views Each Type of Training

Let’s make this easy:

✔ OSHA Accepts In-Person Training

…as long as it covers all required topics and includes hands-on practice.

✔ OSHA Accepts On-Site Training

…because it naturally includes site-specific hazards, which OSHA loves.

❌ OSHA Does NOT Accept “Online-Only” for Fall Protection

You can do theory online, but hands-on practice is mandatory.

❗ Employers Must Document Everything

No matter which format you choose, OSHA requires:

- Trainee name

- Date of training

- Signature of trainer

- Training topics covered

- Proof of competency

Format doesn’t matter. Quality and documentation do.

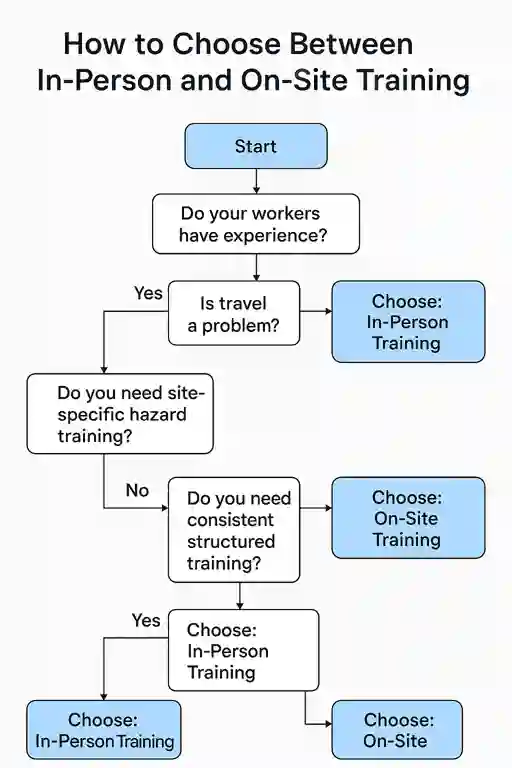

So Which One Should You Choose? Here’s the Real Answer

It depends on your crew, your operations, and your reality on the ground. Here’s the breakdown based on what I’ve seen:

| Scenario | In-Person Recommended? | On-Site Recommended? | Why This Choice Makes Sense |

|---|---|---|---|

| Training brand-new workers | ✔ Yes | ✖ Not Ideal | In-person offers structured learning, controlled environment, and better introductory demonstrations. |

| Training experienced workers | ✔ Optional | ✔ Yes | On-site matches real tasks, equipment, and hazards experienced workers already deal with. |

| Large crews needing training at once | ✖ Not Practical | ✔ Yes | On-site saves time, avoids travel, and allows training in batches throughout the day. |

| Busy job sites with tight schedules | ✖ Not Recommended | ✔ Yes | On-site keeps workers on the job, avoids downtime, and is easier to schedule around work. |

| Companies with multiple job sites | ✔ Yes | ✔ Yes | In-person provides consistent training; on-site offers site-specific hazard coverage. |

| Worksites with unique hazards (towers, warehouses, rooftops) | ✖ Limited | ✔ Yes | On-site training allows the instructor to address real hazards directly. |

| Companies needing a site safety audit | ✖ No | ✔ Yes | On-site trainers can identify unsafe anchors, damaged equipment, and hidden fall hazards. |

| Workers needing advanced rescue training | ✔ Yes (demo rigs available) | ✔ Yes (site-specific) | Both formats work, but training centers often have more advanced rescue demo setups. |

| Teams who need consistency across locations | ✔ Yes | ✖ Not as consistent | In-person ensures standardized delivery for all groups. |

| Training before a high-risk project begins | ✔ Good | ✔ Excellent | Both formats work, but on-site training tailors risk awareness to the project layout. |

| Companies with limited equipment on-site | ✔ Yes | ✖ Not Ideal | Training centers provide full demo gear (lifelines, mock roofs, SRLs, anchors). |

Choose In-Person Training When…

- Your workers are new or inexperienced

- You need “clean and consistent” training

- You want high-quality demonstrations

- Your job sites change frequently

- You don’t want distractions

This is the most structured, reliable option.

Choose On-Site Training When…

- Your crew already knows the basics

- You want training to match the actual hazards

- You want the trainer to inspect your site for risks

- You want max convenience

- You want OSHA-friendly site-specific training

This is the most practical, real-world option.

Real-World Example: When On-Site Beats In-Person

I remember training a roofing crew at their warehouse. During the hands-on portion, I asked:

“Show me where you usually tie off.”

They pointed to a chimney stack they normally used as an anchor point.

We walked over… and the mortar around the chimney was cracked and crumbling. If someone fell and loaded that anchor?

The chimney would have snapped clean off.

Would we have caught that in an in-person training center?

No way.

That’s the value of on-site training.

Real-World Example: When In-Person Beats On-Site

I trained a group of manufacturing workers once—great people, but their site was tiny and didn’t have any proper fall protection systems installed yet.

At the training center, the workers:

- Used a proper lifeline

- Practiced on elevated platforms

- Tested SRLs

- Saw drop tests

- Practiced rescues

None of that would have been possible on-site.

That’s the value of in-person training.

My Personal Recommendation (Based on Years of Experience)

If you’re training beginners → start with in-person.

If you’re training experienced crews → choose on-site.

If you want total coverage → do BOTH once a year (many companies do).

For OSHA best practices, the “gold standard” is:

➡️ Initial in-person training

➡️ Annual on-site refresher + site-specific hazard review

That’s the perfect mix of theory, controlled practice, and real-life application.

Final Thoughts

Fall protection training isn’t just a checkbox for OSHA. It’s genuinely about sending people home in one piece. Whether you go with in-person or on-site, the training has to be:

- Clear

- Hands-on

- Site-specific

- OSHA-compliant

- Up to date with equipment and hazards

Both formats can get you there—you just need to match the training style to your crew’s reality.

If your workers learn better with structure?

Go in-person.

If your workers learn better by doing?

Go on-site.

At the end of the day, the “best” training is the one that actually changes behavior and prevents falls.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

View All Articles