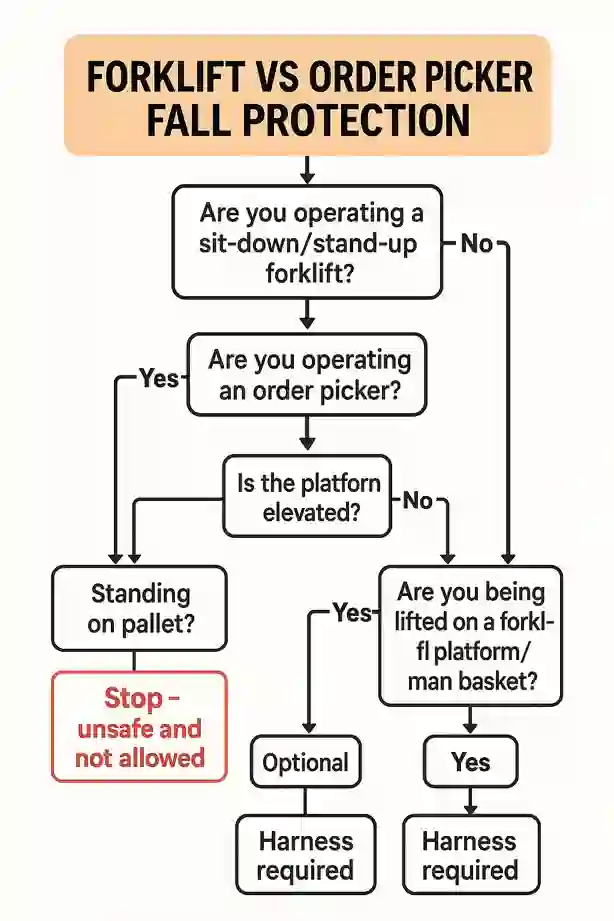

Let me tell you something I’ve learned from years of working in warehouses, construction sites, and pretty much anywhere you can park a forklift: the question of fall protection always comes up. Almost every new operator has asked me the same thing at some point:

“Do I need to wear a harness while driving a forklift?”

And every time, I give them the same answer — and it usually surprises them.

No, you don’t need a harness just to drive a forklift.

But — and this is the part everyone misses — there ARE situations where fall protection suddenly becomes mandatory, and OSHA is very clear about those.

So let’s break this down in simple, real-world terms. No lawyer talk. No stiff safety manual tone. Just straight experience and what the OSHA rulebook really means when you’re actually out there doing the work.

Why Most Forklift Operators Don’t Need Fall Protection

If you’re sitting in the operator’s seat, doing normal forklift stuff — loading trucks, moving pallets, running up and down the aisle — you’re not required to wear a full-body harness.

Why? Because forklifts are designed to protect you by keeping you inside the cab, not by tethering you to something.

The seatbelt is your fall protection.

OSHA doesn’t want you climbing or jumping out of the forklift during a tip-over. They want you to stay inside the protective frame (called the “overhead guard” or “cage”). The seatbelt keeps you from being thrown out.

I’ve seen operators skip the seatbelt because “they’re only moving 10 feet.” And I’ve seen the consequences too — tip-overs happen fast, and you don’t have time to think. Staying inside the protective zone saves your life.

So remember:

Driving the forklift = Seatbelt required.

No harness required.

Simple.

But… when your feet leave the ground? That’s a whole different story.

But what If You’re Using an Order Picker? Do You Need Fall Protection?

Yes — fall protection is ALWAYS required on an order picker.

Because your whole body goes up with the forks, OSHA treats an order picker as an elevated work platform, just like a scissor lift or boom lift.

Why Fall Protection Is Required

- Your feet leave the ground.

- You’re typically above OSHA’s 4-foot trigger height.

- You’re exposed to open edges.

- The machine is designed for you to ride up with the load.

So OSHA requires:

- Full-body harness

- Tie-off to the approved anchor point

- 100% tie-off any time the platform is raised

Most units have a built-in SRL, so operators just clip in.

OSHA Rules That Apply

- 1910.178 — Powered Industrial Trucks

- 1910 Subpart D — Walking-Working Surfaces (elevated platforms, edges)

- Manufacturer instructions — also enforceable by OSHA

All major brands clearly state: Tie off before elevating.

Short Version

👉 Order Picker = Always Wear a Harness + Always Tie Off When Elevated.

No exceptions.

If You Don’t Tie Off

- Falls can happen instantly — even from 6–8 feet.

- Many buildings store product 20–40 feet high.

- Real-world near misses show the SRL can literally save a life.

Operator Quick Checklist

- Clip into the designated anchor point

- Confirm SRL retracts/locks

- Stay inside platform rails

- Don’t climb racks or stand on pallets

- Don’t override safety switches

What About Driving on the Ground?

If the platform isn’t raised, OSHA doesn’t require tie-off — but most companies still do it to build safe habits.

When Fall Protection Is Required on a Forklift

| Equipment Type | Is Fall Protection Required? | What OSHA Says | What Operator Must Wear | When It Applies |

|---|---|---|---|---|

| Sit-Down Forklift | ❌ No | Seatbelt is required; harness not required for normal driving | Seatbelt | Anytime the operator is driving or lifting loads |

| Stand-Up Forklift | ❌ No | Same as sit-down; operator must stay inside the compartment | None (Seatbelt if equipped) | Normal operation |

| Order Picker / Order Selector | ✔️ Yes | Operator is elevated → fall protection required | Full-body harness + SRL | Anytime the platform is raised |

| Forklift With Approved Work Platform / Man Basket | ✔️ Yes | Treated like aerial lift | Harness + tie-off to platform | Anytime a person is lifted |

| Improvised Platform (Pallet, crate) | ❌ Illegal | Not allowed by OSHA or manufacturers | N/A | Never permitted |

| Scenario | Fall Protection Required? | Reason |

|---|---|---|

| Driving at ground level | ❌ No | Seatbelt provides protection |

| Operator being lifted in a man basket | ✔️ Yes | Elevated platform = fall hazard |

| Order picker platform raised | ✔️ Yes | Operator is above 4 ft with open edge |

| Changing warehouse lights from forklift basket | ✔️ Yes | Elevated work = fall risk |

| Standing on a pallet to reach inventory | ❌ OSHA violation | No guardrails, no tie-off |

| Leaning over racks above 4–6 ft | ✔️ Yes | Height threshold reached |

There are scenarios where OSHA expects you to use fall protection around forklifts. And if you’ve been in the industry long enough, you’ve probably seen each of these more than once.

Let’s go through them one by one — in plain English.

1. When a Forklift Is Lifting YOU (Work Platforms / Man Baskets)

This is the big one.

If you’re standing on a platform that’s lifted by a forklift — even if it’s just “a few feet” — OSHA now treats that situation like an aerial lift. This means fall protection is required.

But not just any fall protection.

Here’s how OSHA actually wants it done:

- Use a properly approved work platform (not a pallet, not a bin, not a crate).

- The platform must have guardrails.

- You must wear a full-body harness.

- The lanyard must be anchored to the platform — not the forklift mast.

This is a detail many people get wrong. I’ve seen operators clip their lanyard to the forklift itself because “it’s stronger.” Yes, it’s strong. That’s not the issue. The issue is movement. If the mast tilts or moves, you could be thrown off balance.

Anchoring to the platform keeps your movement matched with the platform itself.

Real-world example:

Changing warehouse light bulbs.

Taking inventory on high racks.

Doing quick repairs up high.

If you’re on a forklift platform → harness required, no exceptions.

2. When You’re Working at Height Using a Forklift as a Support

Sometimes you’re not standing on a platform — you’re just up high, leaning over a rack, or doing maintenance. The forklift might be nearby or helping with access.

In these cases, OSHA’s fall protection rules kick in:

- 4 feet for general industry

- 6 feet for construction

If your work puts you above these heights with no guardrails, you need fall protection whether or not a forklift is involved.

This is where I see people get careless. They think, “I’m not being lifted, I’m just climbing.” But OSHA doesn’t care how you got up there — only that you’re up there.

If your feet aren’t on the ground and there’s a fall hazard → fall protection required.

3. When People Do “The Pallet Ride” (AKA: the fastest way to fail an OSHA inspection)

Let me be blunt:

Standing on a pallet lifted by a forklift is illegal and dangerous.

But does it happen?

Oh yeah. All the time.

Shortcuts are tempting. Someone needs something from the top rack. No man basket. No ladder. So someone says, “Hop on the pallet real quick.”

This scenario breaks multiple safety rules at once:

- No proper platform

- No guardrails

- No anchorage point

- No fall protection

- No training

- No communication protocol

If OSHA walks in and sees this, it’s an instant citation. If an accident happens, it’s a huge problem for the company.

If a forklift is lifting you → you need a proper platform AND fall protection.

No pallet. No exceptions.

What OSHA Actually Says (But Explained Like a Human)

Let me translate the key OSHA rules operators always ask about:

| Scenario | Fall Protection Required? | Reason |

|---|---|---|

| Driving at ground level | ❌ No | Seatbelt provides protection |

| Operator being lifted in a man basket | ✔️ Yes | Elevated platform = fall hazard |

| Order picker platform raised | ✔️ Yes | Operator is above 4 ft with open edge |

| Changing warehouse lights from forklift basket | ✔️ Yes | Elevated work = fall risk |

| Standing on a pallet to reach inventory | ❌ OSHA violation | No guardrails, no tie-off |

| Leaning over racks above 4–6 ft | ✔️ Yes | Height threshold reached |

OSHA 1910.178 — Forklift Operation

This is the rule that covers powered industrial trucks.

- It says forklift operators must use seatbelts.

- It says you should not try to jump out during a tip-over.

- It does not say drivers wear harnesses.

OSHA 1910 Subpart D — Fall Protection for General Industry

This kicks in when you’re:

- Working 4 feet or higher

- Exposed to an unprotected edge

- On a platform without guardrails

OSHA 1926.501 — Fall Protection for Construction

This applies at 6 feet or higher.

Work Platforms on Forklifts

OSHA requires:

- Approved man baskets

- Guardrails

- Personal fall protection (harness + lanyard)

- Training for both operator and worker

In simple terms:

If the forklift is lifting a person → fall protection required.

If it’s lifting materials → seatbelt only.

Training Requirements

| Topic | Sit-Down Forklift | Order Picker | Work Platform on Forklift |

|---|---|---|---|

| Operator certification required | ✔️ Yes | ✔️ Yes | ✔️ Yes |

| Fall protection training | ❌ No | ✔️ Yes | ✔️ Yes |

| How to inspect harness/SRL | Not required | Required | Required |

| Tie-off procedure | Not required | Required | Required |

| Elevated work rules | Not applicable | Required | Required |

Common Misunderstandings I See All the Time

After training hundreds of operators, here are the most popular myths.

Myth #1: “We only go up two shelves, it’s not that high.”

If you fall from 5 or 6 feet and hit your head, that’s more than enough to cause serious injury. OSHA doesn’t play with heights.

Myth #2: “I’ll just hold the rack.”

Your hand is not a fall protection system.

Myth #3: “If something happens, I’ll jump.”

Trust me — you won’t. Forklift accidents happen in fractions of a second. The safest thing to do is stay put with your seatbelt on.

Myth #4: “Harnesses are only for boom lifts.”

Nope. They’re required in any elevated work platform unless guardrails alone are enough.

Myth #5: “Clipping to the mast is fine.”

Absolutely not. The mast moves independently of the platform. If it tilts, you tilt.

When You DO Need Fall Protection: Real-World Scenarios

Let me give you a few real-life examples so you can picture it clearly.

Scenario 1: Taking inventory on a forklift work platform

Harness required ✔️

Scenario 2: Changing a light fixture from a basket

Harness required ✔️

Scenario 3: Driving the forklift normally

Seatbelt only ✔️

Scenario 4: Standing on pallets lifted by forks

Illegal ❌

Unsafe ❌

No fall protection ❌

Major OSHA violation ❌

Scenario 5: Leaning over racking 10 feet high

Fall protection required ✔️ (OSHA height rule applies)

How to Stay Safe Without Overthinking Everything

Look, forklift operators already have plenty to think about. Pedestrians, blind spots, unstable loads, tight aisles — adding complicated fall protection rules on top can make people tune out.

So here’s the rule I teach every new operator:

👉 **If the forklift is lifting YOU, wear fall protection.

If the forklift is lifting MATERIAL, your seatbelt is your fall protection.**

That’s it.

If you just follow that one rule, you’re 90% compliant already.

Here are a few extra tips to stay safe:

1. Don’t use makeshift platforms.

If it doesn’t have guardrails and an anchorage point, don’t stand on it.

2. Don’t climb onto racking.

I’ve seen people climb like ninjas onto pallet racks. Don’t.

3. Never tie off to the forklift.

The platform is the only place to tie off.

4. If you’re unsure, ask for training.

Even experienced operators need refreshers sometimes.

A Quick FAQ (Real Questions Operators Always Ask)

Do I need a harness while driving?

No — just your seatbelt.

Do I need a harness in a forklift man basket?

Yes, absolutely.

Can I stand on a pallet?

No. It’s illegal and unsafe.

Can I tie off to the forklift?

No. Tie off to the platform only.

Does OSHA require training for using a work platform?

Yes. Both the operator and the worker need specific training.

Can I climb the forklift mast?

No. Ever.

Final Thoughts — Fall Protection on Forklifts Isn’t Complicated

A lot of people overcomplicate this topic because they mix up forklifts and aerial lifts. Forklifts are designed to lift things — not people. When you’re just driving the forklift, all OSHA wants is for you to wear your seatbelt and follow safe operating procedures.

But the moment you become the “load” — meaning you’re the one getting lifted — everything changes. Fall protection becomes mandatory. The rules get stricter. And honestly? It makes sense. A fall from even a few feet can cause serious injuries.

If you stick to the simple guideline:

Seatbelt when driving.

Harness when lifted.

…you’ll stay safe, compliant, and out of trouble with OSHA.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

View All Articles