If I had a dollar for every fall protection rope I’ve seen that should’ve been retired years ago, I’d probably have enough money to buy every guy on the crew a new harness. I’m not even kidding—people treat ropes like they’re immortal.

Maybe it’s because ropes look tough. Maybe it’s because “it still looks fine” becomes the universal excuse. Or maybe it’s because replacing a rope feels like a hassle or an expense that can wait until “next week.”

But here’s the truth most people learn the hard way:

A rope doesn’t have to look destroyed to be unsafe.

And when a fall happens, that rope is the only thing standing between you and the ground.

That’s why knowing when to retire a fall protection rope isn’t some boring safety rule—it’s a survival skill.

Let’s break this down…

First Thing’s First: Ropes Don’t Come With a Magic Expiration Date

I’ve had guys ask me, “Hey, how long do these ropes last? Five years? Ten years?”

I wish it were that easy. But the truth is:

There is no one-size-fits-all expiration date.

Some ropes might last years because they’re treated right. Others die young because someone left them in the back of a truck under a pile of metal tools and spilled diesel.

Here’s what decides a rope’s lifespan:

- How often it’s used

- How it’s stored

- What conditions it’s exposed to

- Whether it’s been overloaded

- If it’s taken any shock load

- General wear and tear

So no, you can’t just go by the date on the tag. You have to rely on inspection, experience, and common sense.

When to Retire Fall Protection Ropes

| Retirement Trigger | Why It Matters |

|---|---|

| Rope involved in a fall | Internal fibers may be damaged even if the rope looks fine |

| Visible cuts or abrasions | Indicates weakened fibers and reduced strength |

| Glazing/melted areas | Heat damage compromises fiber integrity |

| Stiff or crunchy spots | Sign of chemical or structural breakdown |

| Flat spots | Fibers crushed or broken |

| Fuzzy/frayed appearance | Outer sheath and inner fibers degrading |

| Chemical exposure | Can weaken rope fibers invisibly |

| UV damage/discoloration | Sunlight slowly degrades strength |

| Unknown history | Cannot verify safety or condition |

| Missing label | No way to confirm ratings or lifespan |

| Fails inspection | Fails any part of the check → unsafe |

| Manufacturer recommends retirement | Overrides all other factors |

The Golden Rule: If the Rope Has Been in a Fall… It’s Done

I don’t care if it looks perfect.

I don’t care if the guy swears he “only fell a little bit.”

I don’t care if “it held me fine.”

If that rope absorbed fall arrest forces even once, it’s retired on the spot.

Ropes are like car seatbelts — one major impact, and they’ve done their job. Their internal fibers could be weakened, stretched, damaged, or structurally compromised even if you can’t see it.

There’s no repairing it. There’s no “testing it.”

You just retire it. End of story.

Visible Damage: The Stuff You Can See With Your Own Eyes

| Check For… | Yes = Retire Rope |

|---|---|

| Fraying/fuzziness | ✔ |

| Cuts or nicks | ✔ |

| Glazing/melted spots | ✔ |

| Flat or crushed areas | ✔ |

| Stiff/crunchy feel | ✔ |

| Color fading/discoloration | ✔ |

Now let’s talk about the things you can see. These are the obvious red flags — the ones that make you go, “Yeah, that rope’s had a rough life.”

Here’s a list of things that should immediately tell you it’s time to retire your rope:

Fraying or Fuzziness

If the rope looks like it’s growing hair, that’s not “character” — that’s wear. Fibers are breaking down.

Cuts, Nicks, or Abrasions

Rope fibers don’t appreciate rubbing on steel edges all day. Even small abrasions can lead to big failures.

Glazing or Melted Spots

These shiny, slick-looking areas happen when the rope has been exposed to too much friction or heat. Welding sparks are another killer.

Stiff or Crunchy Sections

A rope should be flexible. If it feels hard or weirdly stiff, something’s wrong inside.

Flat Spots

A rope is supposed to be round. When it’s flat in spots, that means fibers are crushed or damaged.

Discoloration

Chemical exposure or UV damage can bleach or darken rope fibers. That’s a sign of weakening.

If you see it, retire it. Don’t argue with the rope.

Invisible Damage: The Stuff Most People Never Think About

Here’s where people get into trouble—not all damage is visible.

Some ropes fail without ever looking “bad.”

Let’s talk invisible damage:

Chemical Exposure

Solvents, paints, oils, acids, even strong cleaners can weaken fibers quietly.

A rope that soaked in something unknown? Don’t trust it.

UV Damage

Sunlight slowly eats away at synthetic fibers. A rope that lives outdoors 24/7 ages faster than you think.

Moisture + Mildew

If a rope stays wet in storage, mildew or rot can weaken it from the inside out.

Age-Related Fiber Weakness

Even if stored well, old fibers lose flexibility, strength, and reliability.

You can’t see any of this, but your life depends on remembering it.

| Type of Damage | Examples | Why It’s Dangerous |

|---|---|---|

| Visible Damage | Cuts, fraying, glazing, flat spots, stiffness | Indicates fibers are physically compromised |

| Invisible Damage | Chemical exposure, UV degradation, moisture/mildew, internal fiber damage | Weakens rope from the inside; not always visible |

Manufacturer Rules Matter More Than Pride or Opinions

I’ve been on enough jobsites to know how people think:

“This rope still feels strong.”

“I’ve used way worse.”

“I’m not throwing that away.”

Look — nobody cares how you feel about the rope.

The manufacturer has retirement guidelines for a reason.

Typical retirement guidelines are about 5–10 years, depending on:

- rope type

- material

- frequency of use

- storage conditions

- model-specific instructions

But again: inspection always overrides age.

A rope can be 2 years old and still be trash if it’s been abused.

How Often Should You Inspect Your Rope? Probably More Than You Think

Here’s how I was trained, and how I train others now:

Before Every Use

A quick hands-on inspection.

Run the rope literally through your hands — you’ll feel things your eyes won’t catch.

After a Fall (Yes, Every Single Time)

No exceptions. You retire it.

Periodic Detailed Inspection

A deeper inspection done by a competent person.

This includes checking labels, stitching, connectors, and identifying hidden damage.

Whenever Something Feels “Off”

If something doesn’t feel right, don’t use it. Trust your gut — it’s usually smarter than we give it credit for.

Red Flags You Should Never Ignore

Some things automatically mean the rope is done. No debate.

If your rope has ANY of these issues, consider it retired:

- It feels crunchy

- It’s stiff in certain spots

- The outer sheath slides separately from the core

- It has mysterious stains

- It smells like chemicals

- It was stored in the sun for months

- You have no idea where it came from

- The label is gone and you can’t verify anything

- It’s older than the manufacturer’s recommended life

- It’s been overloaded

And the worst one:

Someone says, “It’ll be fine—just use it.”

That’s when you immediately don’t.

Storage Mistakes That Kill Ropes Faster Than Use

| Bad Storage Practice | Effect on Rope |

|---|---|

| Leaving rope in the sun | UV damage → weakened fibers |

| Keeping rope wet | Mildew and rot |

| Storing on concrete | Moisture + chemical absorption |

| Tossing under heavy tools | Crushing or cutting fibers |

| Throwing loose in truck bed | Abrasion and impact damage |

| Storing near chemicals | Fume exposure and fiber weakening |

Let me tell you the biggest killers of perfectly good ropes.

It’s not climbing. It’s not normal use.

It’s bad storage.

Here are the most common rope-killing habits I’ve seen on jobs:

Leaving it in the sun

UV rays slowly destroy synthetic fibers.

Keeping it wet

Moisture leads to mildew, rot, and fiber weakening.

Storing it on concrete

Concrete sucks moisture and chemicals straight into the rope.

Tossing it under metal tools

Sharp edges + heavy weight = crushed fibers.

Throwing it loose in the back of a work truck

If your rope is rolling around all day with toolboxes, screws, and debris, it’s aging ten times faster.

Leaving it near chemicals

Even fumes can cause long-term damage.

A rope bag or cabinet can literally double a rope’s lifespan.

Factors Affecting Rope Lifespan

| Factor | Impact on Lifespan |

|---|---|

| Frequency of use | High use = faster wear |

| Storage conditions | Good storage extends lifespan |

| Exposure to environment | Sun, heat, chemicals shorten lifespan |

| Material type | Different fibers age differently |

| Load history | Shock loads drastically reduce lifespan |

| Jobsite conditions | Abrasive or dirty environments age ropes fast |

“When in Doubt, Throw It Out”: The Rule That Never Fails

I know people hate this rule because it sounds wasteful.

But think of it this way:

A $150 rope is cheaper than a hospital bill.

A $150 rope is cheaper than a funeral.

If you’re hesitating, you already know the answer. Doubt is usually your brain warning you that something is wrong.

Workers who retire gear early aren’t wasteful — they’re the ones who go home unharmed.

Common Jobsite Excuses (And Why They’re Dangerous)

I’ve heard every excuse in the book. Let me break down a few:

“It still looks okay.”

Not how rope retirement works.

“We’ll replace it next week.”

Next week is a long time when your life hangs on that rope.

“We’ve used worse.”

That’s not a badge of honor — that’s luck.

“It’s expensive to replace.”

Not as expensive as a fall.

“We don’t have a spare rope right now.”

Then you also don’t have a safe way to work.

“Just be careful with it.”

If you have to “be careful” because the rope is already questionable, that’s already the problem.

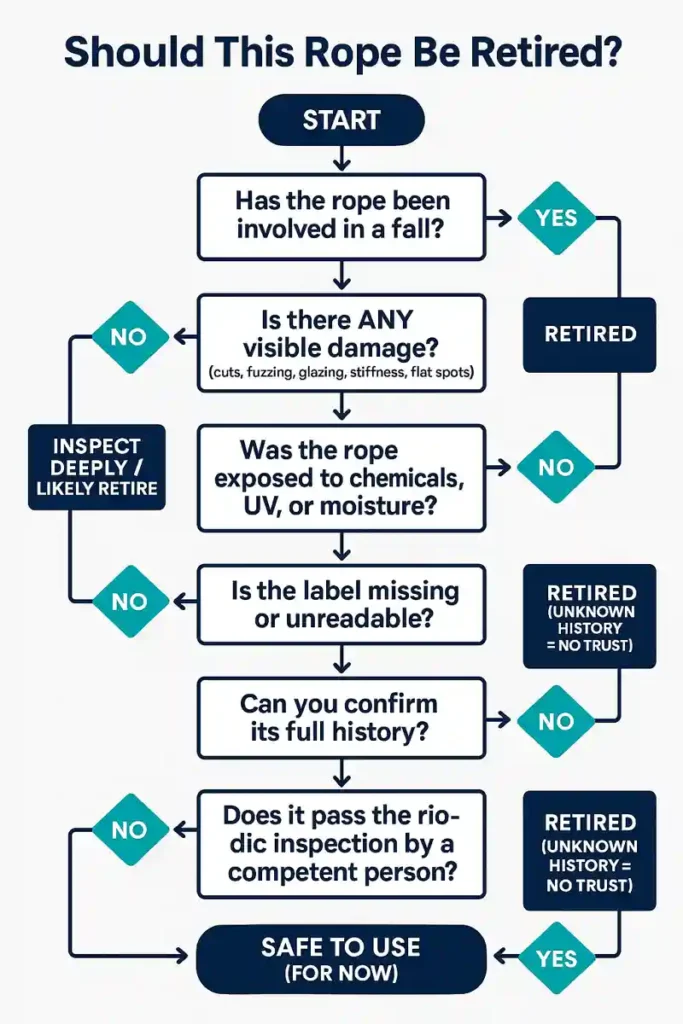

A Quick Checklist: When Should You Retire a Rope?

If your rope hits ANY of these, it’s done:

- It was involved in a fall

- Visible damage (cuts, fraying, glazing)

- Hard/stiff/crunchy sections

- Flat spots

- Chemical exposure

- Unknown history

- Fuzzy/furry appearance

- Discoloration

- Missing label

- Failed inspection

- Manufacturer says retire it

- Gut feeling says something’s off

If you need to talk yourself into using the rope, that means you shouldn’t.

The Bottom Line: Your Rope Won’t Save You If You Don’t Save It

Here’s the plain and simple truth:

Fall protection ropes don’t last forever, and they don’t owe us anything. They work hard, they get beat up, and they eventually reach a point where they can’t do their job safely anymore.

Your responsibility — my responsibility — is to know when that time has come.

Not out of fear.

Not because OSHA says so.

But because every worker deserves to go home in one piece.

A rope will never speak up and say, “Hey, I’m done.”

It’ll just fail. And when it does, it’s always without warning.

So stay sharp, inspect often, store correctly, and when you’re not sure — retire it.

Your life is worth more than a rope.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

View All Articles