Let’s be honest: scaffold work looks simple from the ground. You climb up, you start working, and that’s that. But anyone who’s spent time on a jobsite knows scaffolds can get sketchy real fast. And the biggest thing that trips people up—besides loose planks—are the fall protection rules.

I’ve seen everything: guys walking on a 20-foot-high platform with no guardrails, workers tying their harness to the scaffold itself, planks that bounce like trampolines, and crews who swear up and down that “OSHA only cares if you’re above six feet.”

Nope. Not true.

So let’s cut the confusion and talk about what OSHA actually expects when you’re working on scaffolds. I’m going to explain it the same way I would if we were standing on the jobsite together.

Let’s Clear This Up Before You Step on That Scaffold

Everybody thinks fall protection rules are complicated. Honestly? They’re not. The problem is people try to apply general industry rules to construction rules, or they mix up ladder rules with scaffold rules, or they rely on “what someone told me once.”

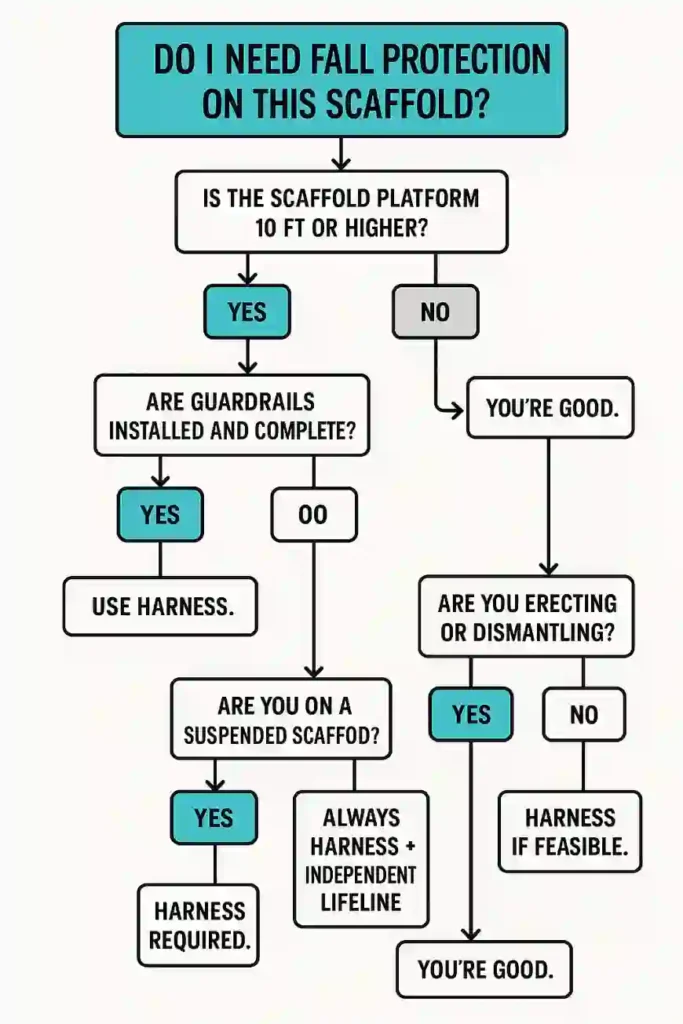

Here’s the simple version:

👉 For scaffolds, OSHA cares about one magic number: 10 feet.

If the platform is 10 feet or higher, fall protection is required. Period.

Now, OSHA isn’t picky about which fall protection you use. They only care that you use something—guardrails, a harness, or another approved method. But you need the right one for the right situation.

Let’s walk through it so you never have to guess again.

Fall Protection Scaffold Workers Must Use

| Scaffold Type / Work Situation | Required Fall Protection | OSHA Rule / Height Trigger | Simple Explanation (Casual Tone) |

|---|---|---|---|

| Supported Scaffold (10 ft or higher) | Guardrails OR Personal Fall Arrest System (Harness) | 1926.451(g)(1) | Once you hit 10 ft, you need protection. Guardrails usually do the job. |

| Supported Scaffold (Below 10 ft) | Not required (but recommended) | — | You’re not legally required, but it’s still smart to use rails if you can. |

| When Guardrails Are Missing | Full-body harness + lifeline | 1926.451(g)(1)(vii) | No rails? Then you must clip in—no exceptions. |

| Suspended Scaffold (Any height) | Harness + independent lifeline | 1926.451(g)(3) | If the platform hangs on ropes, you’re wearing a harness 100% of the time. |

| Scaffold Erecting or Dismantling | Fall protection if feasible | 1926.451(g)(2) | OSHA gives flexibility, but most sites now require tying off. |

| Narrow Scaffold (Under 18-inch platform) | Harness required | 1926.451(b) | If the platform is too skinny, rails aren’t enough—clip in. |

| Platforms With No Full Planking | Harness required | 1926.451(b)(1) | Gaps = fall hazards, so OSHA expects fall arrest protection. |

| Scaffolds Near Open Edges, Shafts, or Drop-Offs | Harness required | Exposure-based rule | If there’s an opening beside you, tie off—simple as that. |

| Rolling/Mobile Scaffolds (10 ft or higher) | Guardrails or harness | 1926.452(w) | Same 10-ft rule applies. But don’t ride the scaffold while it moves. |

| Pump Jack Scaffolds | Guardrails or harness (at 10 ft) | 1926.452(j) | Once you’re up high, you need rails or a harness—it’s that straightforward. |

| Ladder Jack Scaffolds | Harness required | 1926.452(k) | These are lightweight, so OSHA wants a harness at all times. |

| Roof-Bracket Scaffolds | Guardrails or harness | 1926.452(m) | Most roofs don’t have guardrails, so workers usually go with a harness. |

| Jump Scaffolds / Cantilevered Scaffolds | Harness required | Manufacturer specs + OSHA | Anything sticking out or unsupported needs fall arrest protection. |

| Scaffold Over Water | Harness or guardrails + life jacket (if needed) | Maritime guidan |

Scaffold Fall Protection Requirements (By Scenario)

| Scaffold Type / Work Situation | Required Fall Protection | OSHA Rule / Height Trigger | Simple Explanation (Casual Tone) |

|---|---|---|---|

| Supported Scaffold (10 ft or higher) | Guardrails OR Personal Fall Arrest System (Harness) | 1926.451(g)(1) | Once you hit 10 ft, you need protection. Guardrails usually do the job. |

| Supported Scaffold (Below 10 ft) | Not required (but recommended) | — | You’re not legally required, but it’s still smart to use rails if you can. |

| When Guardrails Are Missing | Full-body harness + lifeline | 1926.451(g)(1)(vii) | No rails? Then you must clip in—no exceptions. |

| Suspended Scaffold (Any height) | Harness + independent lifeline | 1926.451(g)(3) | If the platform hangs on ropes, you’re wearing a harness 100% of the time. |

| Scaffold Erecting or Dismantling | Fall protection if feasible | 1926.451(g)(2) | OSHA gives flexibility, but most sites now require tying off. |

| Narrow Scaffold (Under 18-inch platform) | Harness required | 1926.451(b) | If the platform is too skinny, rails aren’t enough—clip in. |

| Platforms With No Full Planking | Harness required | 1926.451(b)(1) | Gaps = fall hazards, so OSHA expects fall arrest protection. |

| Scaffolds Near Open Edges, Shafts, or Drop-Offs | Harness required | Exposure-based rule | If there’s an opening beside you, tie off—simple as that. |

| Rolling/Mobile Scaffolds (10 ft or higher) | Guardrails or harness | 1926.452(w) | Same 10-ft rule applies. But don’t ride the scaffold while it moves. |

| Pump Jack Scaffolds | Guardrails or harness (at 10 ft) | 1926.452(j) | Once you’re up high, you need rails or a harness—it’s that straightforward. |

| Ladder Jack Scaffolds | Harness required | 1926.452(k) | These are lightweight, so OSHA wants a harness at all times. |

| Roof-Bracket Scaffolds | Guardrails or harness | 1926.452(m) | Most roofs don’t have guardrails, so workers usually go with a harness. |

| Jump Scaffolds / Cantilevered Scaffolds | Harness required | Manufacturer specs + OSHA | Anything sticking out or unsupported needs fall arrest protection. |

| Scaffold Over Water | Harness or guardrails + life jacket (if needed) | Maritime guidance | Same fall rules, but workers may need flotation gear too. |

The 10-Foot Rule: The Heart of Scaffold Fall Protection

Alright, let’s talk about the rule that gets butchered the most.

OSHA says: If your scaffold platform is 10 ft above a lower level, you need fall protection.

Not 6 feet. Not 4. Not “whenever your foreman feels like it.”

Ten feet.

Now, here’s what people misunderstand:

✔ “Lower level” doesn’t just mean the ground

If you’re on a scaffold 12 feet above a stairwell, balcony, concrete slab, another lower scaffold level—that counts.

✔ The rule also applies on slopes or uneven ground

I’ve seen people argue:

“It’s only an 8-foot scaffold.”

Yeah, maybe on one side. But on the downhill side, it’s 11 feet. OSHA looks at the biggest exposure.

✔ Doesn’t matter if you “feel safe”

I’ve heard workers say this so many times it’s practically a jobsite slogan:

“I’m fine, I’ve done this a thousand times.”

And that’s exactly what people say right before they fall.

Guardrails: Your First Line of Defense (And Usually All You Need)

Let’s start with the simplest, most common option: guardrails.

If your scaffold is 10+ feet high, guardrails generally satisfy OSHA’s fall protection requirement—as long as they’re actually installed correctly, which, trust me, is where many jobsites screw up.

Here’s what OSHA wants on a proper guardrail system:

- Top rail at 38–45 inches high

- Midrail halfway between top rail and platform

- Toe board if there’s a dropped-object risk

- Rails must withstand certain force (don’t worry, just don’t use rusty wire)

But here’s the part workers mess up:

❌ Missing midrails

People remove them thinking “they’re in the way.” Yeah, they were protecting you.

❌ Makeshift rails

PVC pipes, loose lumber, tie wire, zip ties—none of these count.

❌ Rails too low

If the top rail hits your thigh instead of your hip, it’s not a guardrail… it’s decoration.

✔ Guardrails are usually the easiest, safest option

No harness. No lifeline. No tie-off point needed.

Just good old-fashioned rails.

So if guardrails are missing or incomplete:

👉 You need a harness.

No debate.

When You Actually Need a Harness on a Scaffold

This is where people start shaking their heads because they don’t want to wear a harness.

Here’s when OSHA says you must tie off:

| Situation | Harness Required? | Why OSHA Requires It | Extra Notes (Casual Tone) |

|---|---|---|---|

| Guardrails are missing or incomplete | YES | No rails = nothing stopping a fall. | If the rails aren’t up yet, your harness is your guardrail. |

| Suspended scaffold (any height) | YES — always | Platform hangs from ropes → higher risk. | You also need an independent lifeline just for you. |

| Erecting or dismantling scaffolds | YES, if feasible | This is when the scaffold is least stable. | Modern sites almost always require tie-off. |

| Platform is narrower than 18 inches | YES | Too narrow for safe footing or guardrails alone. | Easy to slip or step off. Clip in. |

| Platform missing full planking (gaps) | YES | Gaps create fall-through hazards. | OSHA expects full decking or fall arrest. |

| Working next to openings, edges, shafts, or drop-offs | YES | Even small gaps can be deadly at height. | If you can fall sideways, tie off. |

| Moving mobile scaffolds (workers on platform) | YES — or prohibited | Scaffold can tip while moving. | Don’t ride mobile scaffolds; tie-off if you must be elevated. |

| High winds or unstable conditions | YES | Wind knocks workers off balance easily. | If it feels sketchy, wear your harness. |

| Ladder jack scaffolds | YES | Lightweight and less stable by design. | OSHA requires fall arrest here. |

| Roof bracket scaffolds | YES (if no guardrails) | Roof edges = high fall risk. | Most roof jobs end up with harness use. |

| Cantilevered or “jump” scaffolds | YES | Overhanging platforms increase instability. | Treat them like high-risk scaffolds—tie off. |

🔸 When guardrails aren’t installed

Pretty simple. No rails = harness.

🔸 When you’re on a suspended scaffold

More on that later, but just remember:

If it hangs on ropes, you’re wearing a harness.

🔸 When you’re erecting or dismantling scaffolds

There’s a special rule here—OSHA gives some flexibility—but realistically, you should tie off if it’s feasible.

🔸 When the scaffold is too narrow

Platforms narrower than 18 inches often require personal fall arrest systems.

🔸 When you’re working in areas with weird fall exposures

Such as:

- Open sides into shafts

- Platforms near edges with no guardrails

- Elevated or sloped work surfaces near the scaffold

And please, for the love of safety, do not tie off to the scaffold itself unless the manufacturer allows it.

A lot of scaffolds aren’t engineered to withstand a fall arrest load. One fall can yank the entire system down like a house of cards.

Suspended Scaffolds: Totally Different Rules

| Requirement | OSHA Rule | What It Means (Casual Explanation) | What Happens If You Skip It |

|---|---|---|---|

| Full-Body Harness Required | 1926.451(g)(3)(i) | If the platform hangs from ropes, you MUST wear a harness. No debate, no exceptions. | If something fails, you go straight down. Harness is your only backup. |

| Independent Lifeline Required | 1926.451(g)(3)(ii) | Your harness must connect to a lifeline that is separate from the scaffold’s support ropes. | If the scaffold drops, you go with it. Independent lifeline keeps you alive. |

| Vertical Lifeline for Each Worker | 1926.451(g)(3)(iii) | One lifeline per person. No sharing, no doubling up. | Shared lifelines can tangle or fail—OSHA won’t allow it. |

| Lifeline Must Be Protected From Cuts/Abrasions | 1926.451(g)(3)(iv) | The rope must be guarded from sharp edges, welding, grinding sparks. | A damaged line = catastrophic fall. |

| Anchorage Must Support 5,000 lbs. | 1926.451(g)(3)(i) | Your tie-off point must be strong enough to stop a fall safely. | Weak anchorage rips out and provides zero protection. |

| Both Line and Harness Must Be Compatible | Manufacturer specs | All gear must be rated for fall arrest and work together properly. | Mismatched gear can fail even if it “ |

Suspended scaffolds—swing stages, bosun chairs, platforms held up by ropes—have their own chapter in the OSHA book, and it’s straightforward:

👉 You must wear a harness. Always. No exceptions.

👉 You must attach to an independent lifeline.

Why? Because if a line snaps, a hoist malfunctions, or your platform suddenly tips, that harness is the only thing keeping you alive.

A lot of workers try to tie off to the scaffold frame or the suspension rope.

Nope. Very bad idea. That’s not how suspended scaffolds work.

OSHA wants:

- A full-body harness

- A vertical lifeline

- A separate fall arrest anchor that does not depend on the scaffold staying intact

This setup has saved many lives. I’ve seen platforms drop unexpectedly—it happens fast.

Erecting & Dismantling: The Rule Everyone Misunderstands

OSHA says workers erecting or dismantling scaffolds must use fall protection when feasible.

Now, a lot of people hear “when feasible” and translate it to “do whatever you want.”

That’s not what OSHA meant.

Real talk:

In most situations today, it is feasible. Most companies provide:

- Anchor points

- Horizontal lifeline systems

- Temporary lifeline posts

- Harness-ready work procedures

I’ve seen crews build entire scaffolds 30–40 feet high without tying off “because it takes time.”

Time is never worth your life.

Platforms, Planks, and Safe Access: Part of Fall Protection Too

Fall protection isn’t just about preventing a fall—it’s about preventing the conditions that lead to a fall.

Let’s talk platform safety, the stuff nobody pays enough attention to:

✔ Fully planked platforms

Gaps bigger than 1 inch? Nope.

✔ Scaffold-grade planks

Your cousin’s leftover 2×10 from his house project isn’t scaffold plank.

✔ Secure planks

If they bounce, rock, or slide, that’s a hazard.

✔ Safe access

Don’t climb cross braces—this isn’t American Ninja Warrior.

Use ladders, stair towers, or properly built access.

Special Scaffold Situations You Should Know

Let’s go through a few real-world situations that change your fall protection needs:

⚡ Working near power lines

Stay 10 feet away minimum.

Fall protection doesn’t replace electrocution protection.

🌬 High winds

If the scaffold feels shaky or the planks are rattling—stop work.

Wind takes people off scaffolds every year.

🔨 Handling tools & materials

Dropping a wrench from a 20-foot scaffold turns it into a missile.

Toe boards are required if anyone is working below.

🚫 Riding mobile scaffolds

No matter how many times someone tells you,

do not ride a rolling scaffold.

People get crushed, flipped, or thrown.

Real-World Mistakes I Keep Seeing on Jobsites

I’ve been around long enough to see the same mistakes repeated over and over:

❌ Removing guardrails because they’re “in the way”

They’re not in the way. They’re keeping you alive.

❌ Not tying off on suspended scaffolds

One unexpected jolt and boom—you’re gone.

❌ Tying off to the scaffold frame

Many scaffold frames cannot take a fall arrest load.

❌ Missing planks

Every missing plank is an invitation to a broken leg.

❌ Using makeshift materials

Scaffolds are engineering systems, not DIY projects.

Quick, Simple Checklist: What Fall Protection You Need

Here’s your cheat sheet:

✔ 10 ft or higher?

Use guardrails or a harness.

✔ Guardrails missing or incomplete?

Wear a harness.

✔ Suspended scaffold?

Harness + independent lifeline required.

✔ Erecting or dismantling?

Use fall protection when feasible (which is most of the time).

✔ Narrow platform (<18 inches)?

Harness required.

✔ Working near open edges or unusual exposures?

Harness recommended, sometimes required.

Final Thoughts: Scaffold Safety Isn’t Complicated… If You Know the Rules

Look, scaffold work is part of construction life. Most of us have been up there more times than we can count. But the thing about falls is they don’t give warnings.

You don’t get a second chance.

OSHA’s scaffold fall protection rules aren’t there to make your day longer or annoy you. They’re there because too many workers have been seriously hurt—or worse—doing the exact same tasks you’re doing today.

My rule of thumb is simple:

If you’re wondering whether you need fall protection… you probably do.

When in doubt, clip in. Keep the guardrails up. Don’t rush the setup.

Because at the end of the day, the goal is simple:

Get home the same way you came to work.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

View All Articles