If you’re reading this, chances are you’ve already signed up for fall protection training — or maybe your employer signed you up — and now you’re wondering:

“Am I going to pass the written and practical tests?”

“What if I mess up the hands-on part?”

“What exactly will they ask?”

Take a deep breath.

You’re not alone — almost everyone who sits in that classroom or stands in that training yard feels the same way on day one.

And here’s the truth I’ve learned over years of giving and taking these trainings:

👉 The tests aren’t designed to fail you. They’re designed to keep you alive.

👉 If you understand the basics and practice a little, you WILL pass.

I’ll walk you through everything step-by-step, using real experience, real scenarios, and simple explanations. Imagine you and I are sitting together before your test — this is exactly how I’d coach you.

Read Related Article: How to Become Certified in Fall Protection in 2026? (A Guide)

Before Anything Else: What the Tests Are Actually For

Let’s start with why the written and practical tests exist.

Every year, workers fall from roofs, scaffolds, ladders, and platforms — many of these accidents are preventable. So OSHA requires employers to make sure workers can:

- Understand fall hazards

- Know the equipment

- Recognize what’s safe vs unsafe

- Use their harness and lifeline correctly

The written test checks what you know.

The practical test checks what you can do.

That’s it — no trick questions, no crazy tasks. Just making sure you don’t get hurt.

Read Related Article: 6 Best Places to Get Fall Protection Training

Understanding the Two Tests (So You Won’t Be Surprised)

The Written Test

This is usually multiple choice with some short answers. It covers things like:

- When fall protection is required

- How to inspect a harness

- What counts as a safe anchor

- How lanyards and SRLs work

- Common fall hazards on sites

- Basic OSHA rules

Think of it as your “driver’s permit test” but for safety. They aren’t trying to confuse you — they want to know you understand the basics.

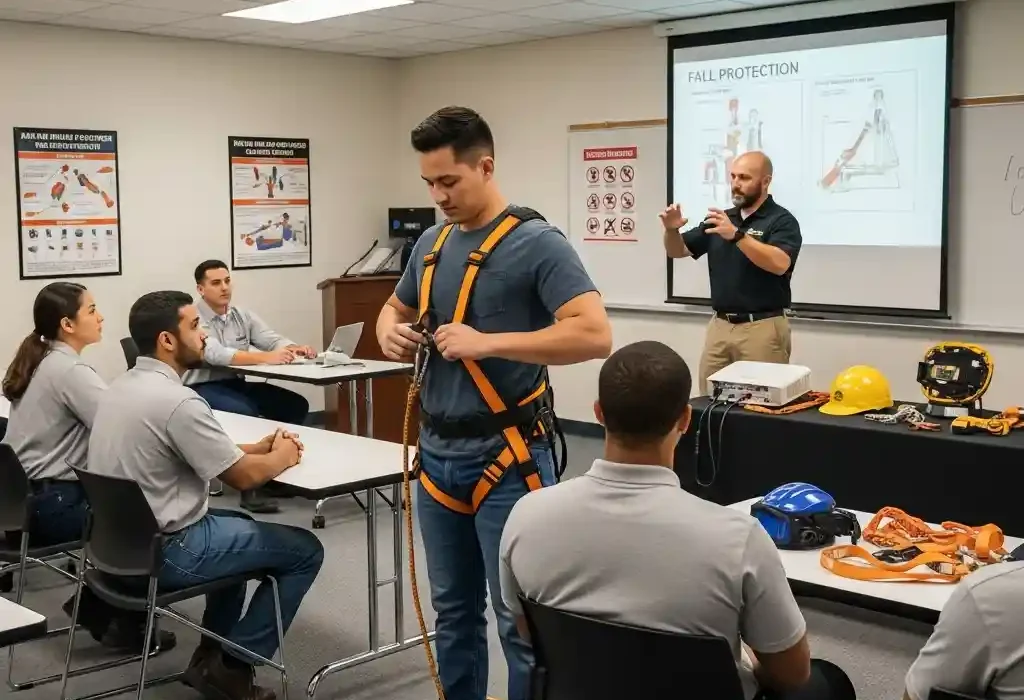

The Practical Test

This is the part most people worry about.

The trainer will ask you to:

- Put on your harness

- Adjust it correctly (not loose!)

- Inspect equipment

- Identify safe and unsafe anchor points

- Show how to tie off

- Demonstrate safe movement near an edge

- Maintain 100% tie off

You’re not expected to be perfect — just safe and confident.

Read Related Article: Does Fall Protection Training Count in Other Countries?

The Written Test: What You’ll See and How to Pass It Easily

Let’s break down the written test first.

Topics You Should Expect

Here are the most common topics that always show up (I say “always” because I’ve seen these questions dozens of times):

| Topic | What You Must Remember | Why It Matters |

|---|---|---|

| Required Heights | 4 ft (General Industry), 6 ft (Construction), 10 ft (Scaffolding) | Knowing when fall protection is required prevents violations and accidents. |

| Anchor Strength | Anchor must support 5,000 lbs per worker or be certified | Prevents anchor point failure during a fall. |

| Harness Inspection | Check webbing, stitching, buckles, D-ring, labels | Ensures your harness won’t fail when you need it most. |

| Common Hazards | Edges, skylights, holes, unstable surfaces, openings | Helps you recognize situations where fall protection is required. |

| Lanyard vs. SRL | Lanyard = more fall distance; SRL = minimal fall distance | Choosing the right equipment reduces risk and clearance needs. |

Read Related Article: Does Fall Protection Training Transfer Between Jobs?

Required fall protection heights

- 4 ft in general industry

- 6 ft in construction

- 10 ft for scaffolding

- Any height when working over hazards like machinery, rebar, or liquids

Harness basics

You should know:

- What each strap does

- How to adjust it

- What the D-ring is for

Equipment inspection steps

You’ll probably see questions about:

- Torn webbing

- Frayed stitching

- Damaged buckles

- Rusted D-rings

- Illegible labels

Anchor point rules

The magic number you MUST remember:

👉 5,000 lbs minimum strength per worker

Or

👉 Engineered system certified by a qualified person

Lanyards & SRLs

You might be asked when to use each one:

- Lanyards = more fall distance

- SRLs = less fall distance, retracting line

What is considered a fall hazard

Skylights, roof edges, holes in floors, unstable surfaces, leading edges, scaffolds.

Read Related Article: Is Your Fall Protection Training Valid in Another State?

How to Pass the Written Test (The Easy Way)

Sample Written Test Questions & Answers

| Question | Correct Answer |

|---|---|

| At what height is fall protection required in construction? | 6 feet |

| What is the minimum strength requirement for an anchor point? | 5,000 lbs per worker |

| What should you inspect on a safety harness before use? | Webbing, stitching, buckles, D-ring, and labels |

| What does 100% tie-off mean? | You must remain connected at all times when exposed to a fall hazard. |

| What type of fall protection device limits fall distance the most? | Self-Retracting Lifeline (SRL) |

| Which of the following is considered a fall hazard? | Unprotected roof edges, skylights, holes, and open platforms |

| Where should the chest strap be positioned on a harness? | Mid-chest level, not on the stomach |

| What should you do if you find damaged fall protection equipment? | Remove it from service and report it immediately |

| What is the purpose of the D-ring on a harness? | It serves as the attachment point for the lanyard or SRL |

| What is the first step when putting on a safety harness? | Locate and hold the back D-ring to orient the harness correctly |

Let me give you the real strategy based on what works for almost all trainees:

1. Focus on the numbers

There aren’t many numbers in fall protection, so the ones that exist are ALWAYS asked.

- 4 ft

- 6 ft

- 10 ft

- 5,000 lbs

2. Understand WHY things matter

If you know why a harness must be snug, you’ll never forget the reason.

Example:

A loose harness means your body can slip or you can hit the structure before the lanyard catches you.

3. Pay attention during the harness demo

Almost all written test questions come from that part of the class.

4. Ask the trainer to repeat anything you’re unsure about

No one thinks you’re dumb — in fact, asking questions shows you’re responsible.

5. Don’t overthink the questions

If two answers look correct, choose the one that is:

- Safer

- Stricter

- More cautious

Safety tests always lean in that direction.

The Practical Test: What You’ll Do and How to Pass Like a Pro

Here’s where most people start sweating… but trust me, this part is almost always EASY if you’ve paid attention.

Let me walk you through each step of the practical test.

Practical Test Tasks & What Evaluators Look For

| Task | What You Must Do | What the Instructor Checks |

|---|---|---|

| Wear Harness | Put it on correctly with no twisted straps | Proper fit, no twists, secure buckles |

| Adjust Harness | Tighten leg, chest, and shoulder straps | Snug fit, chest strap at mid-chest level |

| Inspect Equipment | Check webbing, stitching, buckles, D-ring, and lanyard | Your ability to identify wear and defects |

| Select Anchor Point | Choose a structural anchor capable of 5,000 lbs | Correct, safe, OSHA-compliant anchor |

| Tie-Off | Clip in, check gate lock, maintain 100% tie-off | Proper connection and locking mechanism check |

| Move Near Edge | Walk slowly, stay tied-off, minimize slack | Controlled movement, safe technique |

Putting the Harness On Correctly

This is always Step 1.

Here’s how to do it smoothly:

- Grab the D-ring (the piece on the back).

- Shake the harness so the straps fall into place.

- Put it on like a vest.

- Leg straps first — buckle them snugly.

- Chest strap — at mid-chest level, never on your stomach.

- Shoulder straps — even them out, not twisted.

- Final check — no twists, no slack, all connections secure.

Instructors love workers who take time to make sure the straps are straight and snug.

Pro tip from experience:

If the harness feels comfortable, it’s probably too loose.

Equipment Inspection (They ALWAYS Test This)

You’ll be asked to check:

Harness inspection

- Webbing (cuts, burns, frays, chemicals)

- Buckles (functioning, no rust)

- Stitching (loose threads, broken patterns)

- D-ring (not bent, not rusted)

- Labels (legible)

Lanyard or SRL inspection

- Snap hooks (double action works correctly)

- Cable/webbing (no damage)

- Shock pack (not deployed)

- Connections (no bending)

If you can explain what you’re looking for while inspecting, you will impress the instructor.

Anchor Points

This is the area where many trainees make mistakes.

You’ll be asked something like:

“Show me a safe anchor point.”

Here’s what you must remember:

👉 Has to support 5,000 lbs per worker

👉 Must be structural

👉 Never attach to:

- Guardrails

- Pipes

- Electrical conduit

- Scaffolding rails

- Vents or HVAC units

Good anchor examples:

- I-beams

- Structural steel

- Engineered anchor points

- Installed horizontal lifeline systems

Demonstrating Tie-Off

You will be asked to connect your lanyard/SRL to the anchor.

Here’s how to do it smoothly:

- Approach the anchor safely

- Clip in the snap hook

- Listen for the “click”

- Tug firmly to ensure it locked

- Maintain 100% tie-off at all times

100% tie-off means:

You are ALWAYS connected, even for a few seconds while moving or switching anchors.

Showing How to Move Safely Near an Edge

The trainer might tell you:

“Walk toward that edge and show me how you’d do it safely.”

Here’s what to remember:

- Stay connected

- Move slowly

- Keep eyes on the walking surface

- Don’t step backward

- Keep slack to a minimum

- Use proper footing

If you look calm and in control, you pass.

Common Mistakes That Make People Fail (Avoid These!)

| Mistake | Why It’s Wrong | How to Fix It |

|---|---|---|

| Harness Too Loose | You can slip out during a fall | Tighten leg, chest, and shoulder straps properly |

| Twisted Straps | Reduces strength and causes improper load distribution | Straighten straps before buckling |

| Choosing a Weak Anchor | Anchor may fail during a fall | Always use structural points rated for 5,000 lbs |

| Not Maintaining 100% Tie-Off | You’re unprotected even for a split second | Stay connected at all times, especially when moving |

| Rushing Steps | Causes mistakes and missed inspection points | Slow, steady, deliberate actions |

| Ignoring Snap Hook Gate Check | Gate may not fully lock, creating a fall risk | Always tug after clipping to confirm lock |

I’ve seen these over and over — avoid them and you’re golden:

❌ Wearing harness too loose

❌ Chest strap too low

❌ Twisted straps

❌ Forgetting inspection steps

❌ Picking a bad anchor point

❌ Not maintaining 100% tie-off

❌ Rushing through the steps

❌ Forgetting to check the shock pack

❌ Not checking your snap hook gates

Remember: slow is safe. Safe is correct. Correct is passing.

The Night Before Your Test: Check These

Here’s what I’d tell anyone I was coaching:

✔ Know your heights (4 ft, 6 ft, 10 ft)

✔ Know the 5,000-lb anchor rule

✔ Review the harness inspection sequence

✔ Memorize the common hazards (holes, skylights, edges)

✔ Visualize putting on the harness

✔ Don’t cram — relax

✔ Get good sleep

Even just visualizing the steps helps your confidence skyrocket.

Extra Tips From Real Experience (Things Trainers Don’t Always Tell You)

⭐ Tip #1: They watch your confidence

You don’t have to be perfect — you just have to look like you know what you’re doing.

⭐ Tip #2: Talking while doing helps you pass

Say things like:

“I’m checking the webbing for cuts.”

“I’m making sure the chest strap is at mid-chest.”

“I’m inspecting the shock absorber.”

It shows understanding.

⭐ Tip #3: Ask questions

It shows awareness and responsibility.

⭐ Tip #4: Never joke about safety

Trainers hate that.

⭐ Tip #5: Always pull the snap hook after clipping

This tiny move proves you know how to lock in.

After You Pass: What Happens Next?

Once you pass:

- You’ll receive your certificate or wallet card

- Your employer records your training

- It’s valid until retraining is needed (change of job, new equipment, unsafe behavior, or after an incident)

Don’t throw the certificate somewhere you’ll forget — employers may ask for it later.

Final Thoughts

Let me end with this:

You’re probably nervous right now. Most people are.

But here’s what almost everyone says after taking the tests:

“I was worried for nothing. It was easy once I understood the basics.”

That will be you too.

The written test is straightforward.

The practical test feels like common sense once you understand how the equipment works.

Just remember:

✨ Take your time

✨ Be safe

✨ Check your gear

✨ Move with purpose

✨ Keep 100% tie-off

✨ Don’t overthink it

And most importantly:

These tests aren’t about passing or failing — they’re about making sure you go home safe every day.

You’ve got this.

And I’m here if you want help reviewing, practicing, or preparing even further.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

Mike Pattenson is a construction safety trainer who loves helping workers stay safe on the job. He explains safety in a simple, practical way so crews can easily understand what to do — and why it matters.

View All Articles